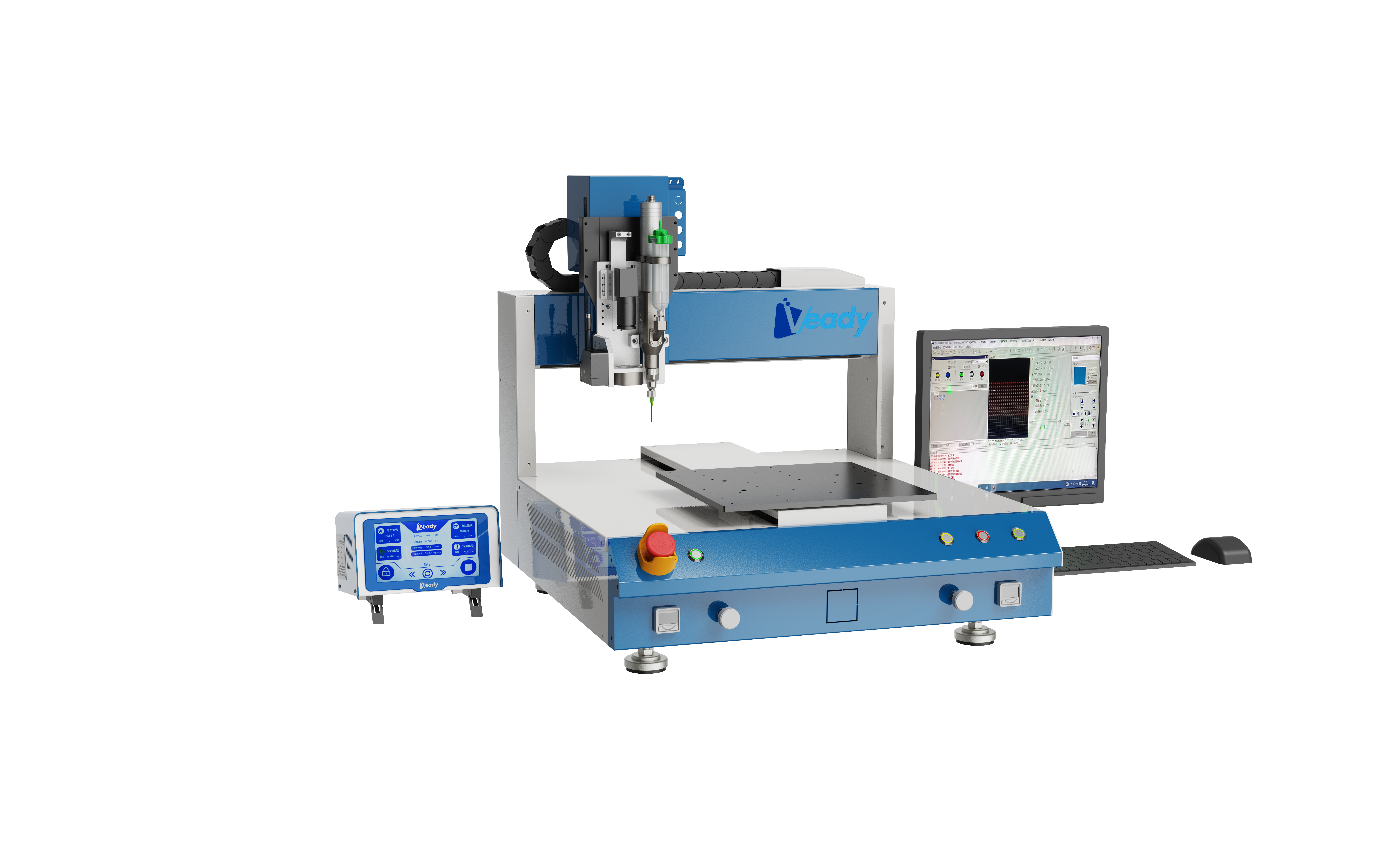

1, using WINDOWS10 operating system, fault sound and light alarm and menu display.

2, CCD visual positioning system, motion module using servo/linear motor drive.

3, maximum working range: 300*300mm.

4, online track height 950mm, track width range 50~300mm, track bearing 5kg.

5, the valve body automatic constant temperature system to ensure the consistent flow of glue.

6, online visual programming /CAD coordinate file import, communication protocol SMEMA.

7, laser height detection system, the workpiece deformation can be automatically calibrated Z axis height.

8, optional workpiece heating system, enhance the flow of the bottom filling paint.

9, precision weight measuring system, intelligent control and detection of dispensing amount, to ensure the consistency of dispensing.

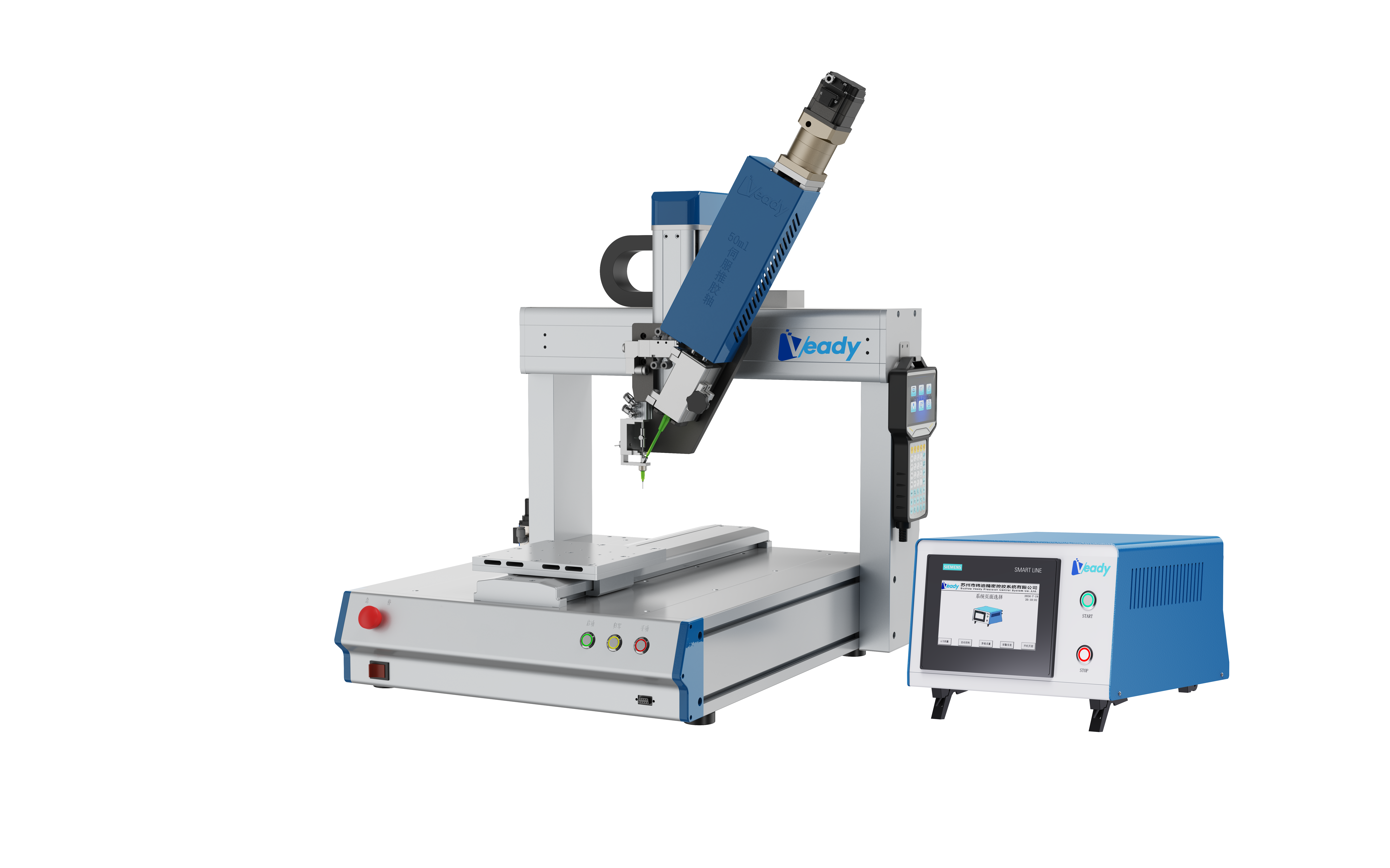

10, optional rotation tilt module can be used for rotation tilt operation dispensing, rotation 90 degrees square, tilt can be about 0~45 degrees.

Scope of application: SMT red glue, bottom filling, component packaging, semiconductor packaging, hot melt glue, LED display, chip fixing, etc.