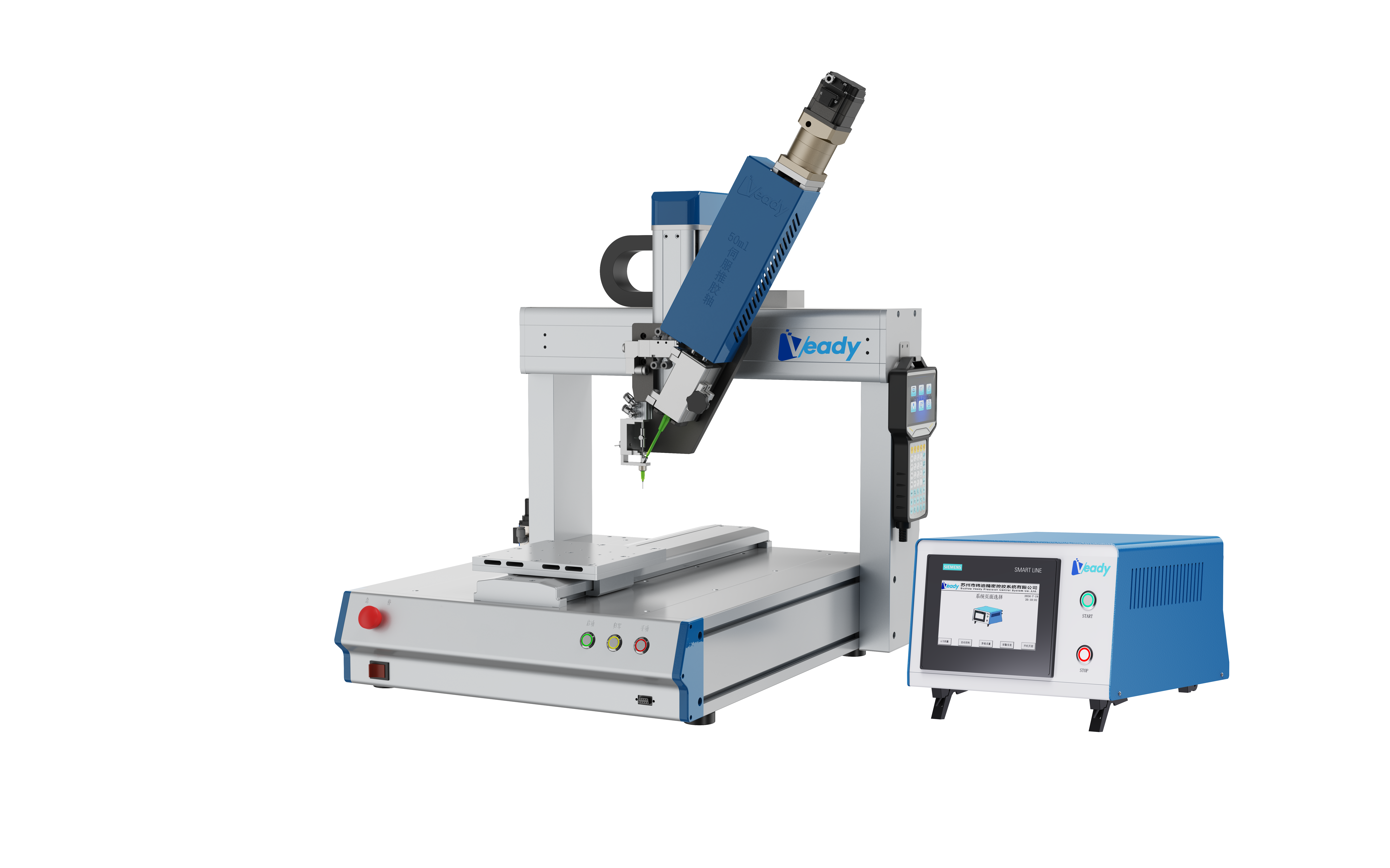

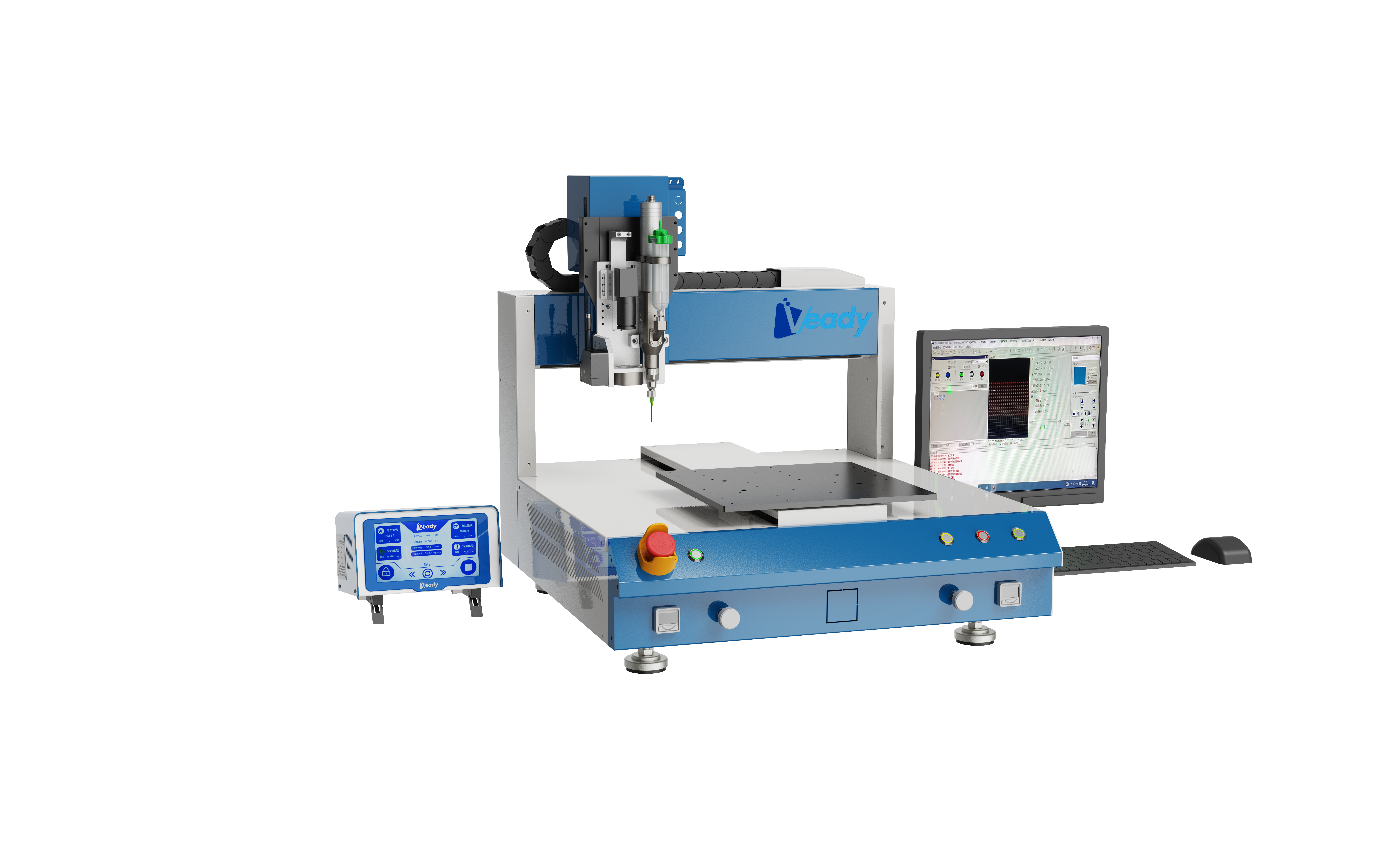

1. Can be matched with piezo valve, gear valve, screw valve, piston valve and other valve applications.

2. Equipped with CCD vision system for automatic positioning/inspection.

3. Configurable with 310ml/600ml cassette drum, 5/55 gallon platen glue supply unit, MFS series stand-alone Material Preparation Systems (capacity 10L, 20L, 45L optional).

4. Independent research and development of dispensing software system, with points, lines, surfaces, arcs, circles and three-axis linkage and other functions, support for free upgrade service.

Applicable glue: epoxy resin, sealant, thermally conductive gel, heat dissipation silicone grease, hot melt adhesive and other single/double component glue.

Application areas: automotive electronics, precision sensors, ignition coils, tire pressure sensing, OBC module seals, engine covers, automotive electronics, connectors and other industries