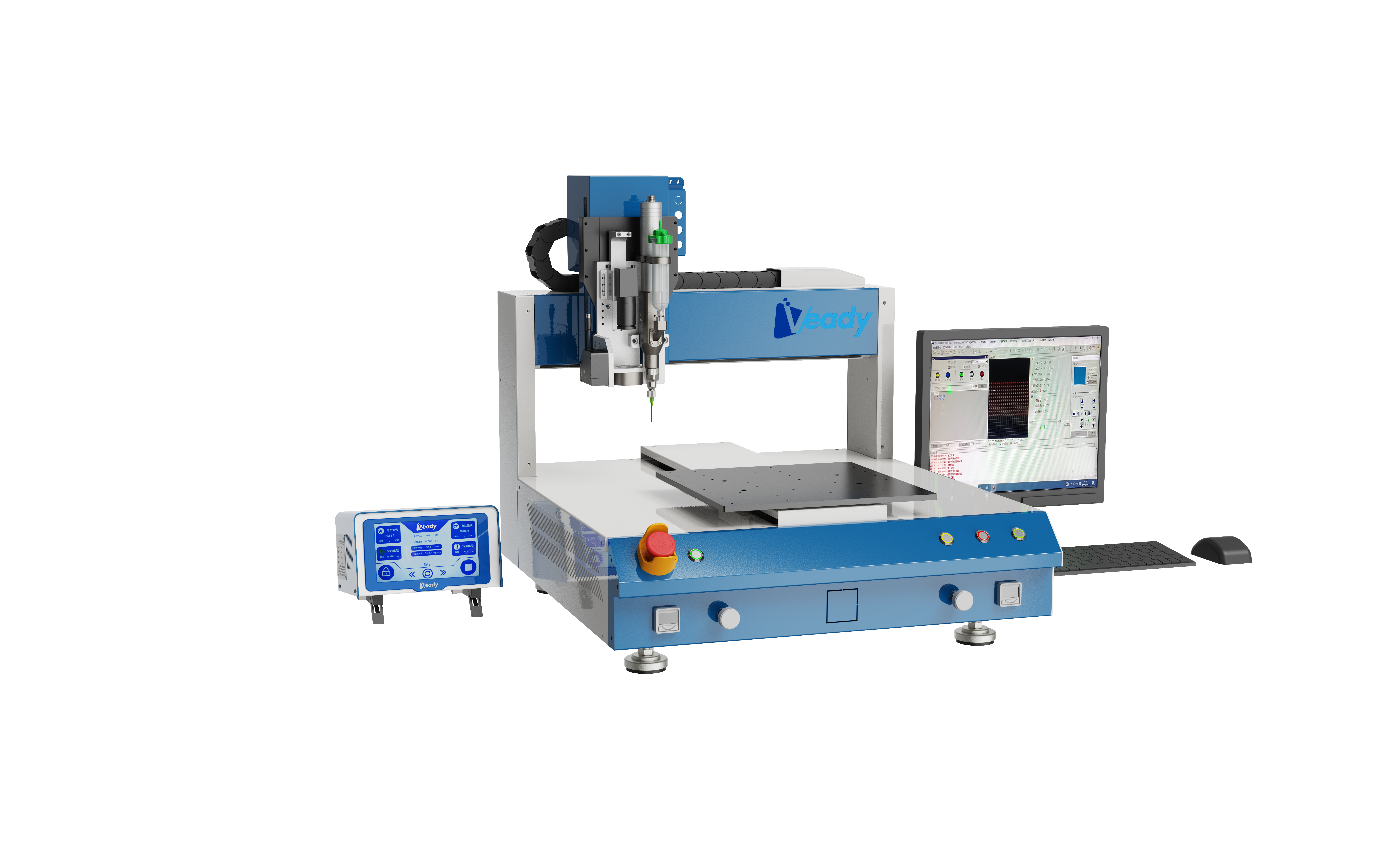

1. PC industrial computer+PLC control system, Chinese operation interface, easy to learn and understand.

2、 The dispensing speed, dispensing time, and stopping time can all be set as parameters, ensuring stable dispensing volume.

3、 It has functions such as point, line, surface, arc, circle, and three-axis linkage, and can adapt to different product points/adhesives.

4、 Online design, capable of achieving positioning for board feeding and conveying.

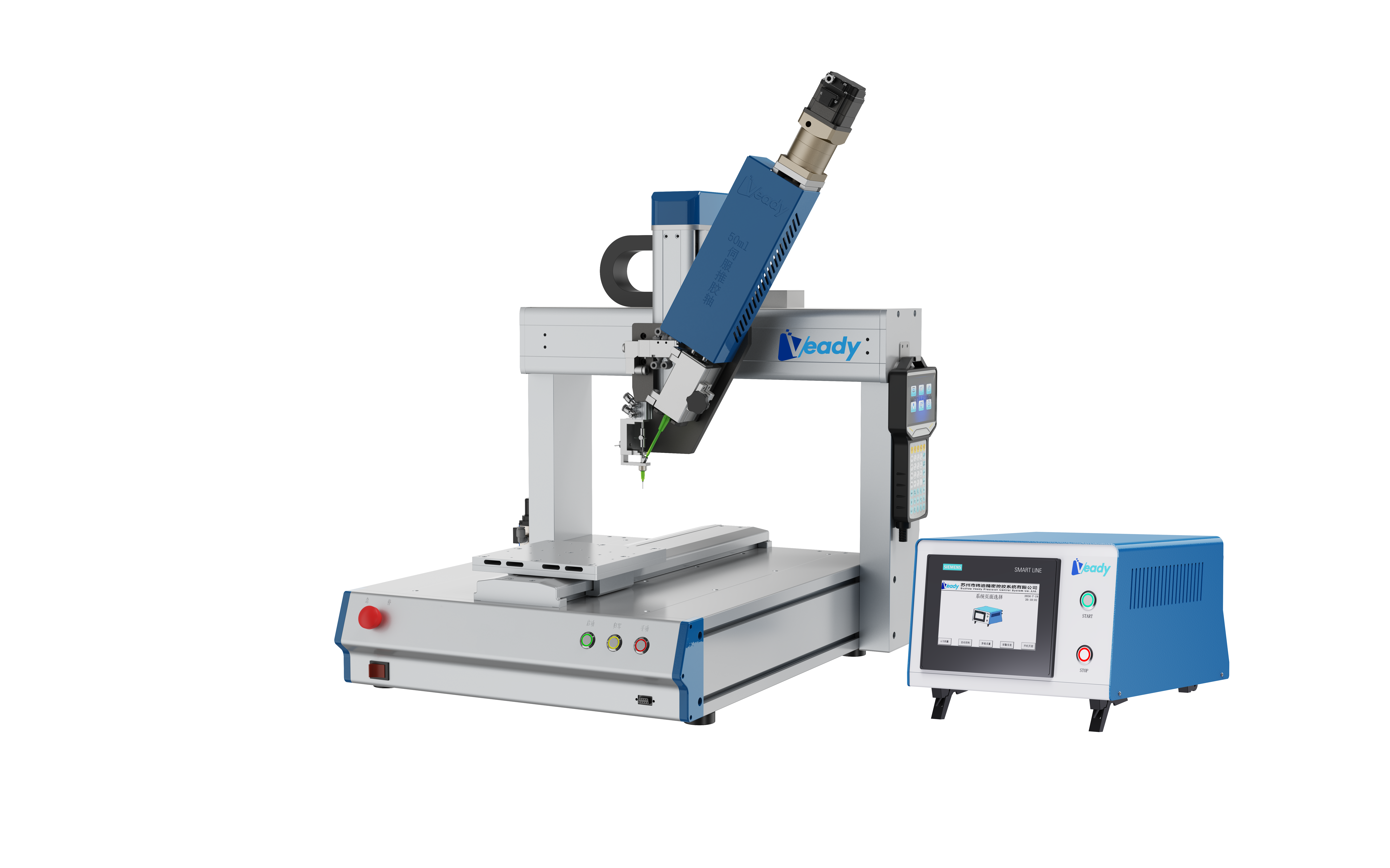

5、 Optional automatic needle alignment, cleaning module, glue weighing, flow meter, barcode scanner, CCD visual positioning, 2D/3D real-time glue path detection module, etc.

6、 Independently developed software system, lifetime free upgrade.

7、 Optional adhesive supply devices such as 300mL/600mL cartridge and 5-gallon pressure plate.

8、 Optional hose/valve body heating and pressure detection functions, compatible with multiple point/glue application processes.

Applicable glue: epoxy resin, sealant, thermal conductive gel, heat dissipating silicone grease and other single/two-component glue.

Applicable industries: automotive electronics, PCB control boxes, gear shift sensors, temperature sensors, power modules, servo motors, IGBT semiconductors, inductor coils, and other products.