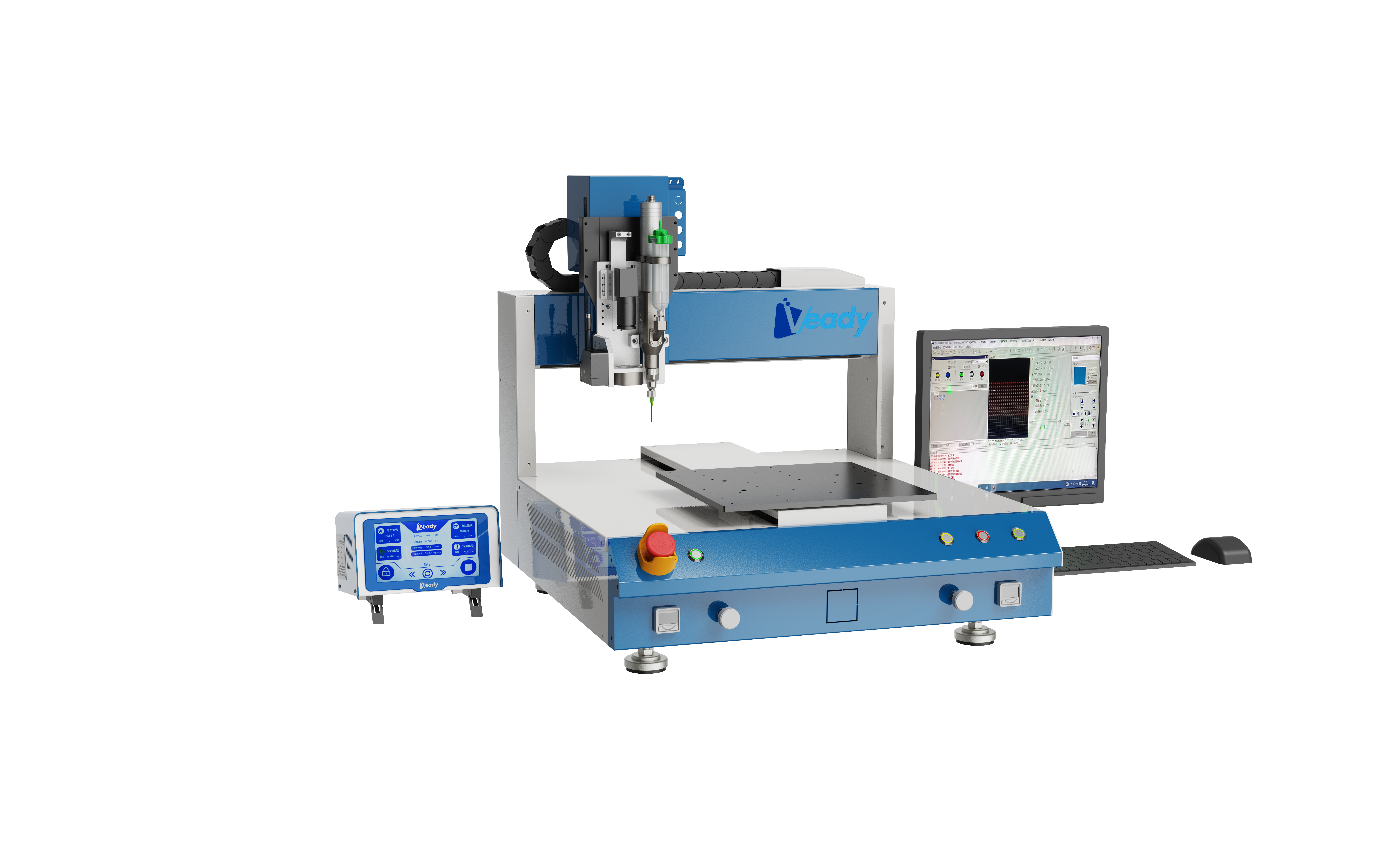

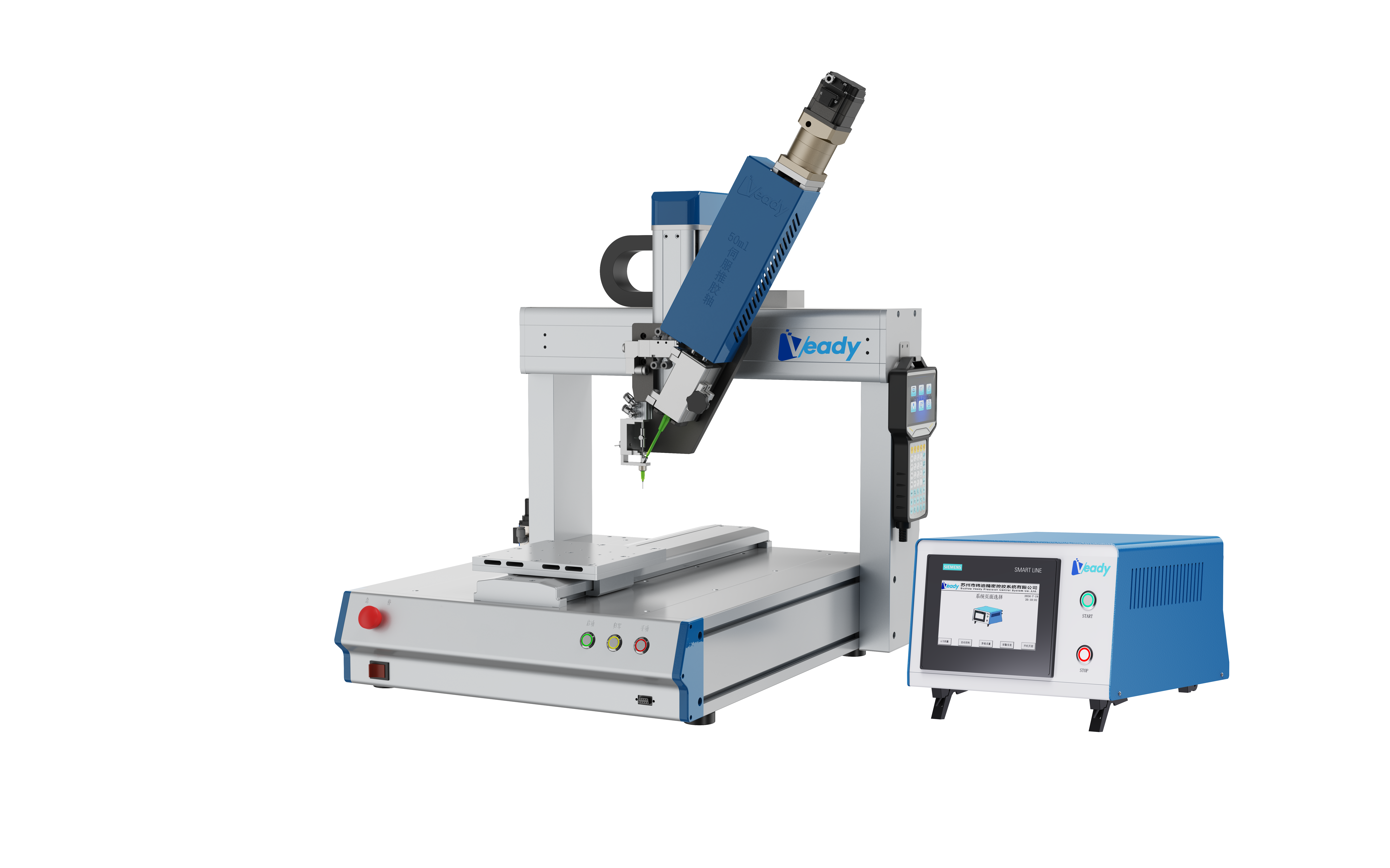

1. Adopt industrial PC control, Windows Operating System, fault sound and light alarm and menu display.

2. CCD visual positioning system.

3. Adopting linear motor+servo motor+screw drive.

4. Can be equipped with: various valve bodies such as pneumatic injection valves and piezoelectric injection valves.

5. Optional laser height detection system can automatically calibrate the Z-axis height after the workpiece is deformed.

6. Optional workpiece heating system can enhance the fluidity of paint during bottom filling.

7. Optional precision weight measurement system can intelligently control and detect the dispensing amount to ensure the consistency of dispensing.