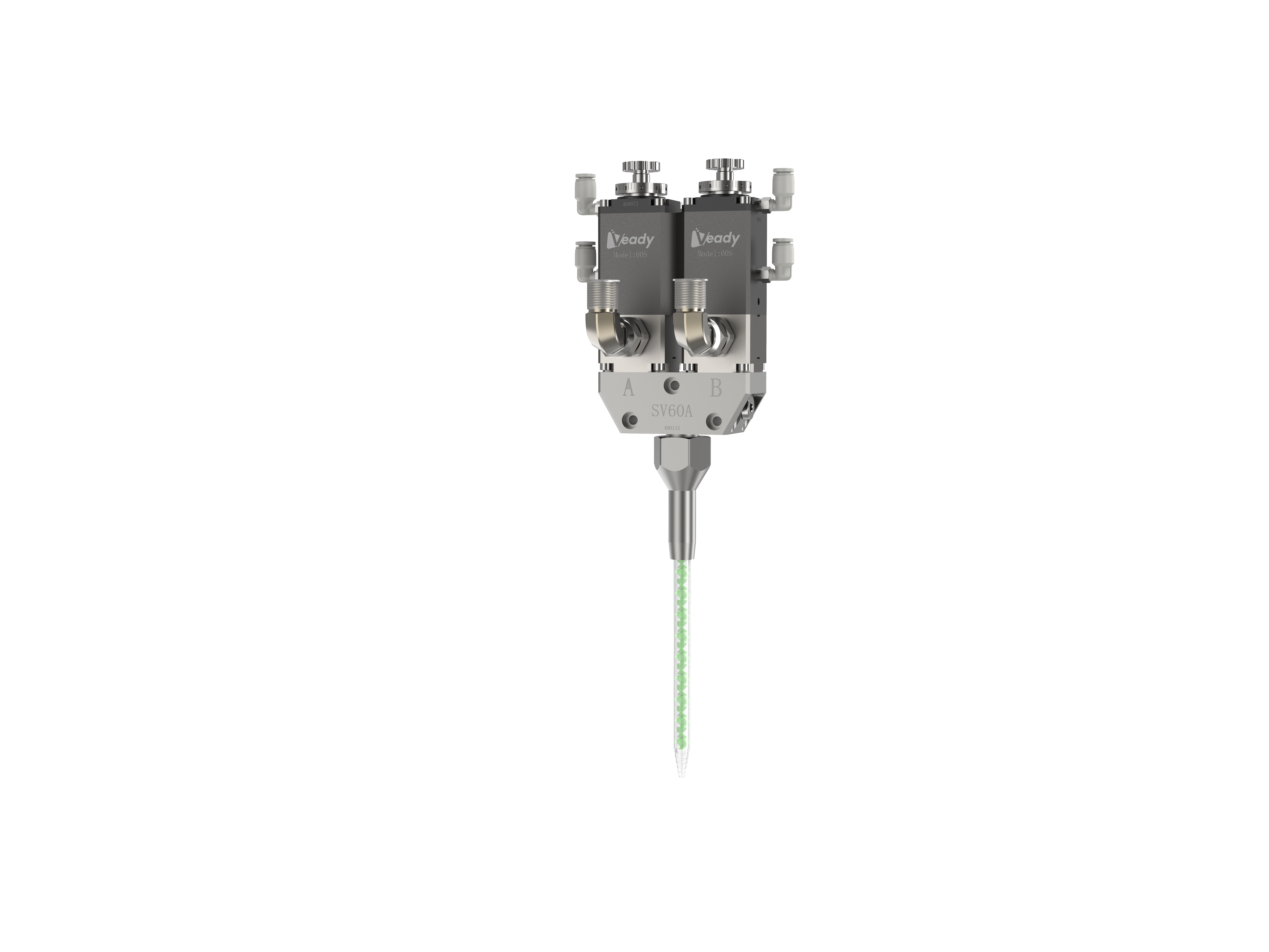

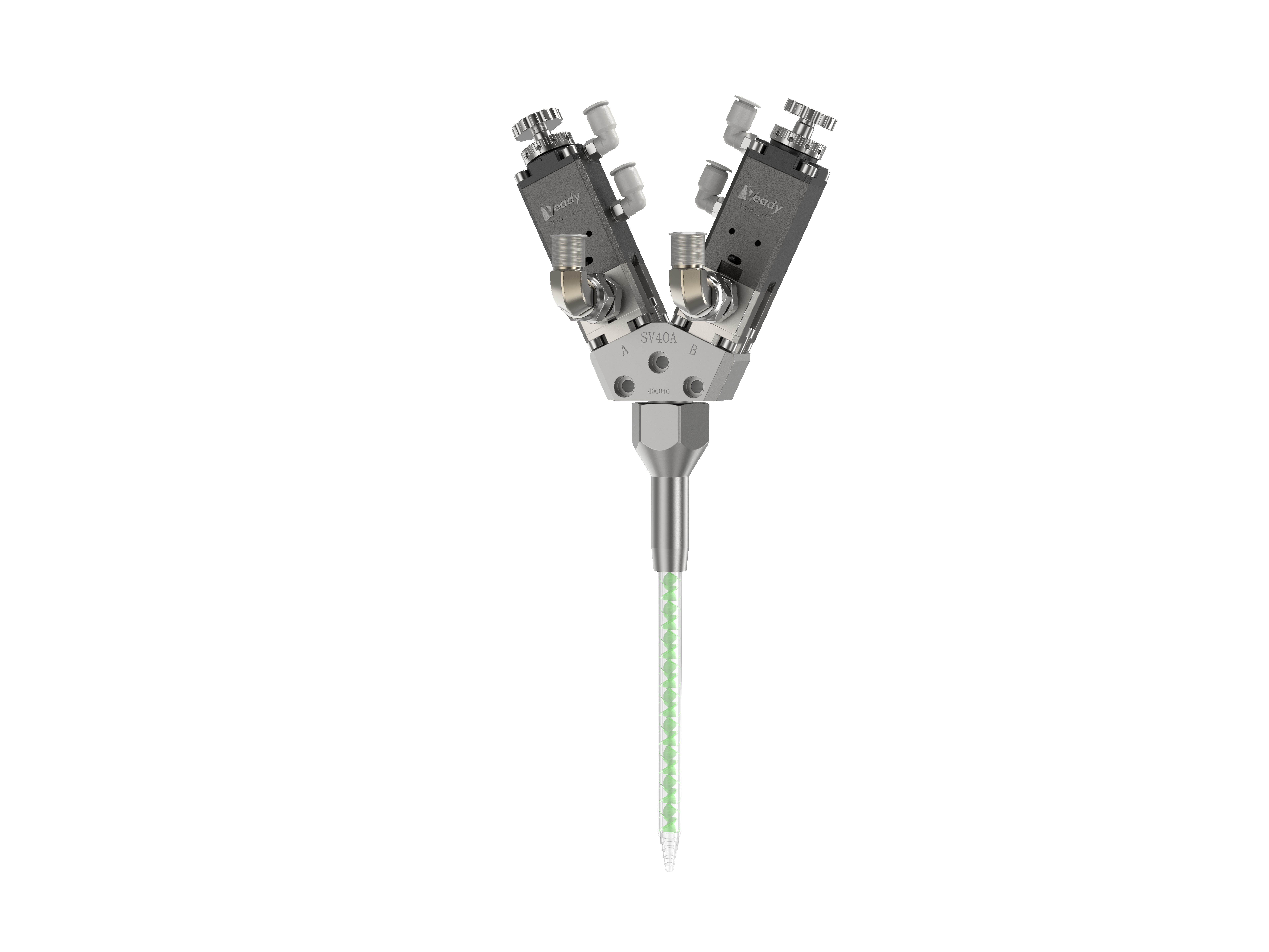

1. Non contact spray dispensing, high-precision dispensing, stable glue point diameter as small as 0.2mm, working frequency up to 500-1000Hz

2. The applicable fluid viscosity range is wide, with a maximum of 200000 mPa.s

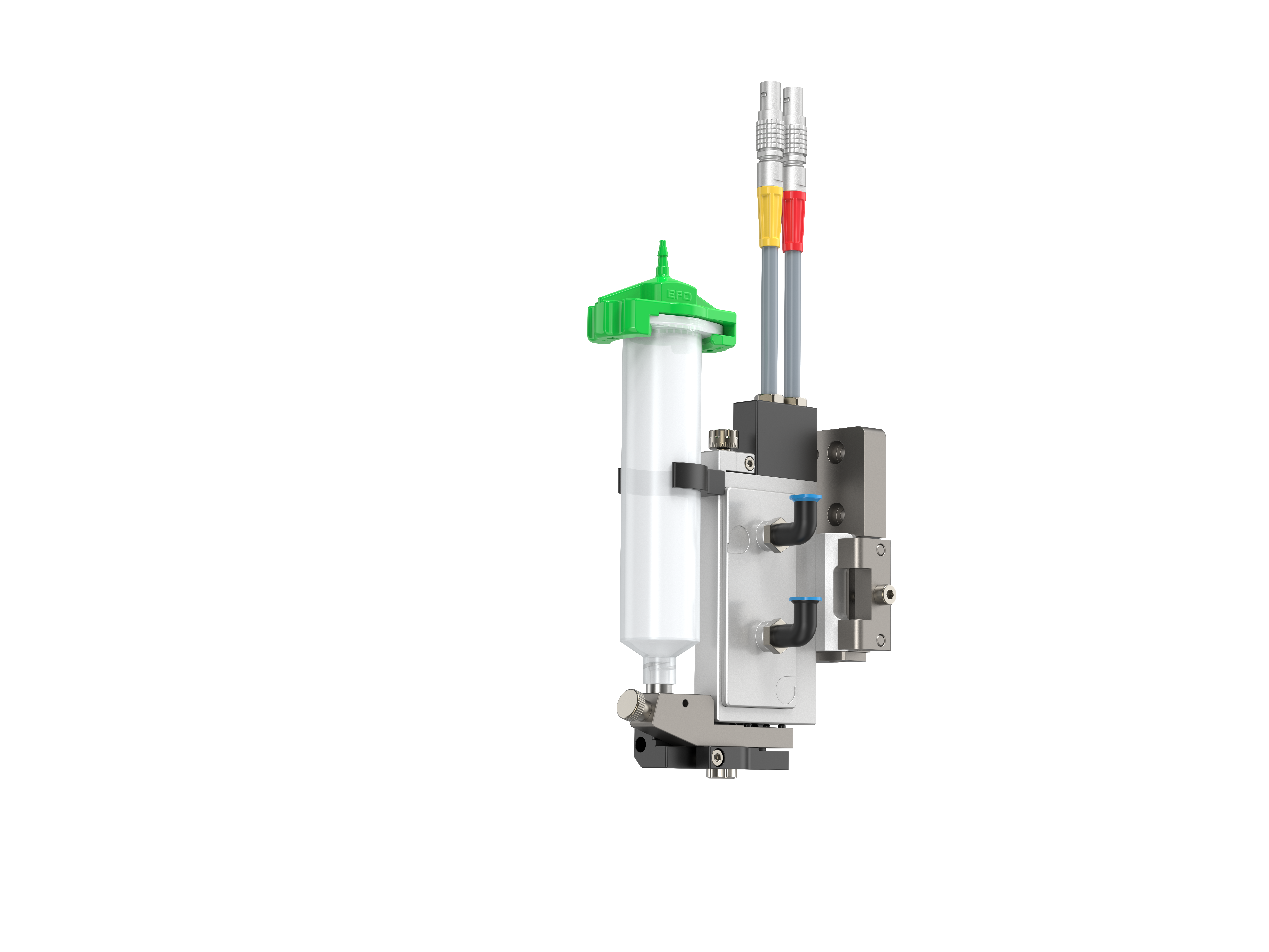

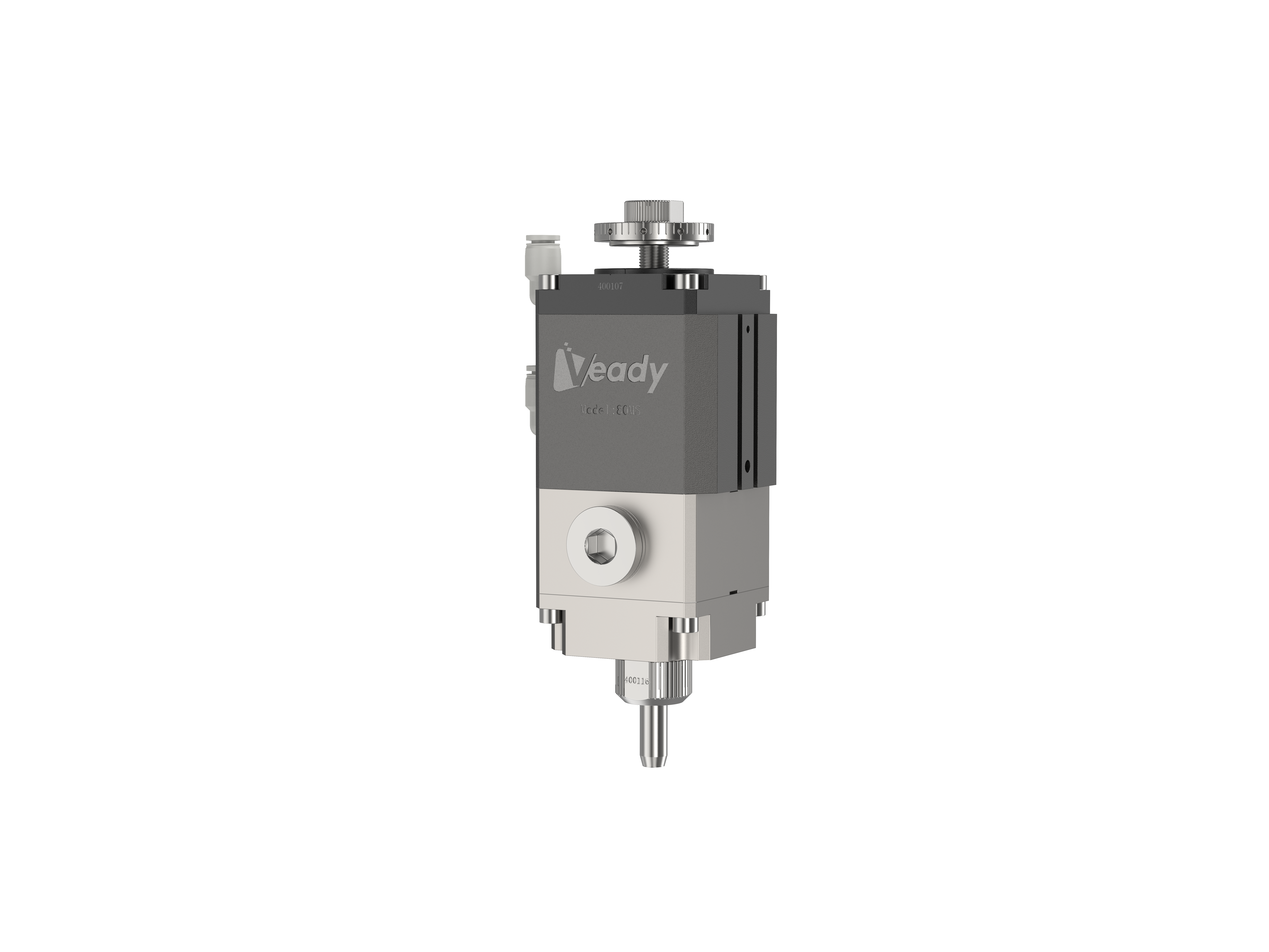

3. Exquisite modular design, easy and fast cleaning

4. Quickly replace parts on site to improve efficiency

5. Quick upper calibration method, convenient for adjusting nozzles

Application areas: Controllable flow and high-speed dispensing operations for various adhesives such as surface mount adhesives, conductive silver paste, IC packaging adhesives, bottom filling adhesives, sealants, surface coating adhesives, etc