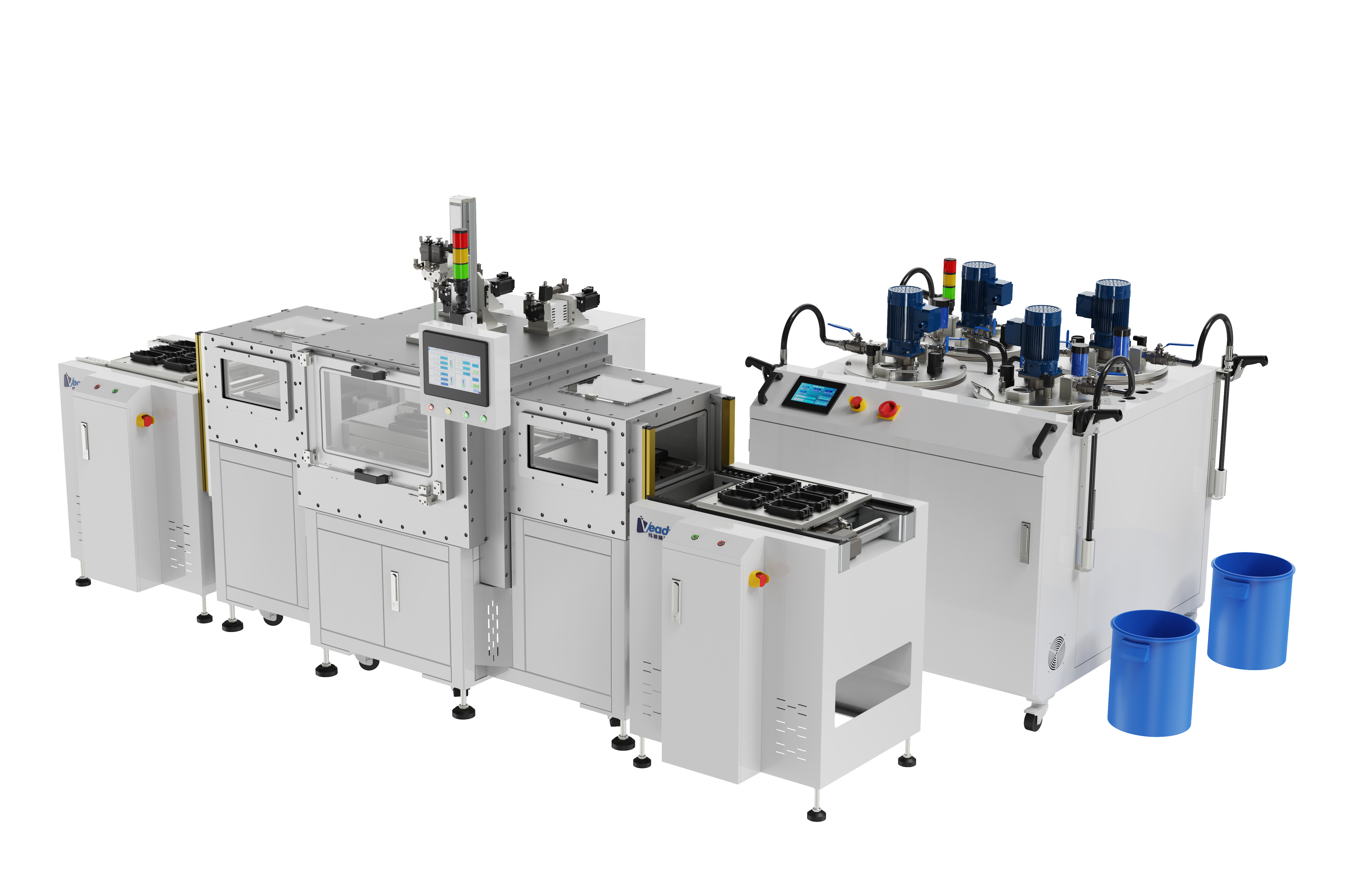

1、 Adopting high-precision piston measurement, four injection heads can operate synchronously, and single control operation is also possible.

2、 From adhesive vacuum treatment to product pre vacuuming, vacuum glue injection, and vacuum pressure maintenance, the entire process operates in a vacuum environment to improve efficiency.

3、 Bottom lifting three-axis operation module with strong compatibility.

4. PLC+PC industrial computer control, realizing production log, product QR code, MES data management.

5、 Four material bucket design, one for backup and one for use, to achieve non-stop glue addition. It can be configured with gear pump, screw pump, plunger pump, and diaphragm pump feeding methods.

6、 The rubber bucket is made of SUS304 stainless steel, which is corrosion-resistant and has a capacity of 10/20/45/60L to choose from.

7、 The rubber drum is equipped with functions such as constant temperature heating, motor stirring, vacuum defoaming, liquid level sensor, and pipeline pressure monitoring.

8、 The vacuum chamber adopts automatic lifting doors or manual opening and closing doors, equipped with safety gratings, ensuring safe and reliable use.

9、 Front and rear connecting platform track conveyor, achieving fully automatic assembly line operation.