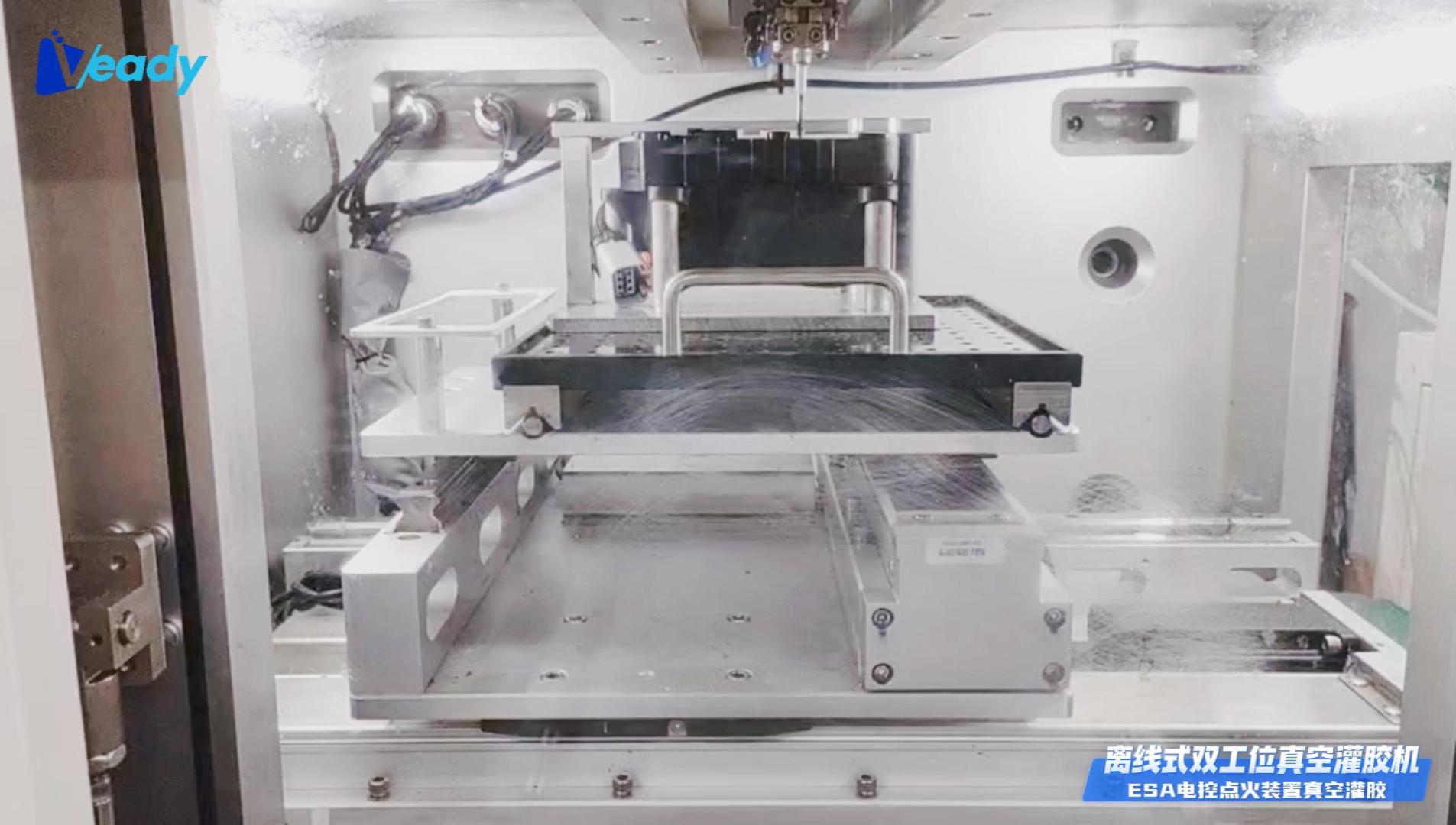

1、 The entire vacuum environment ensures that the product is filled with glue without any bubbles.

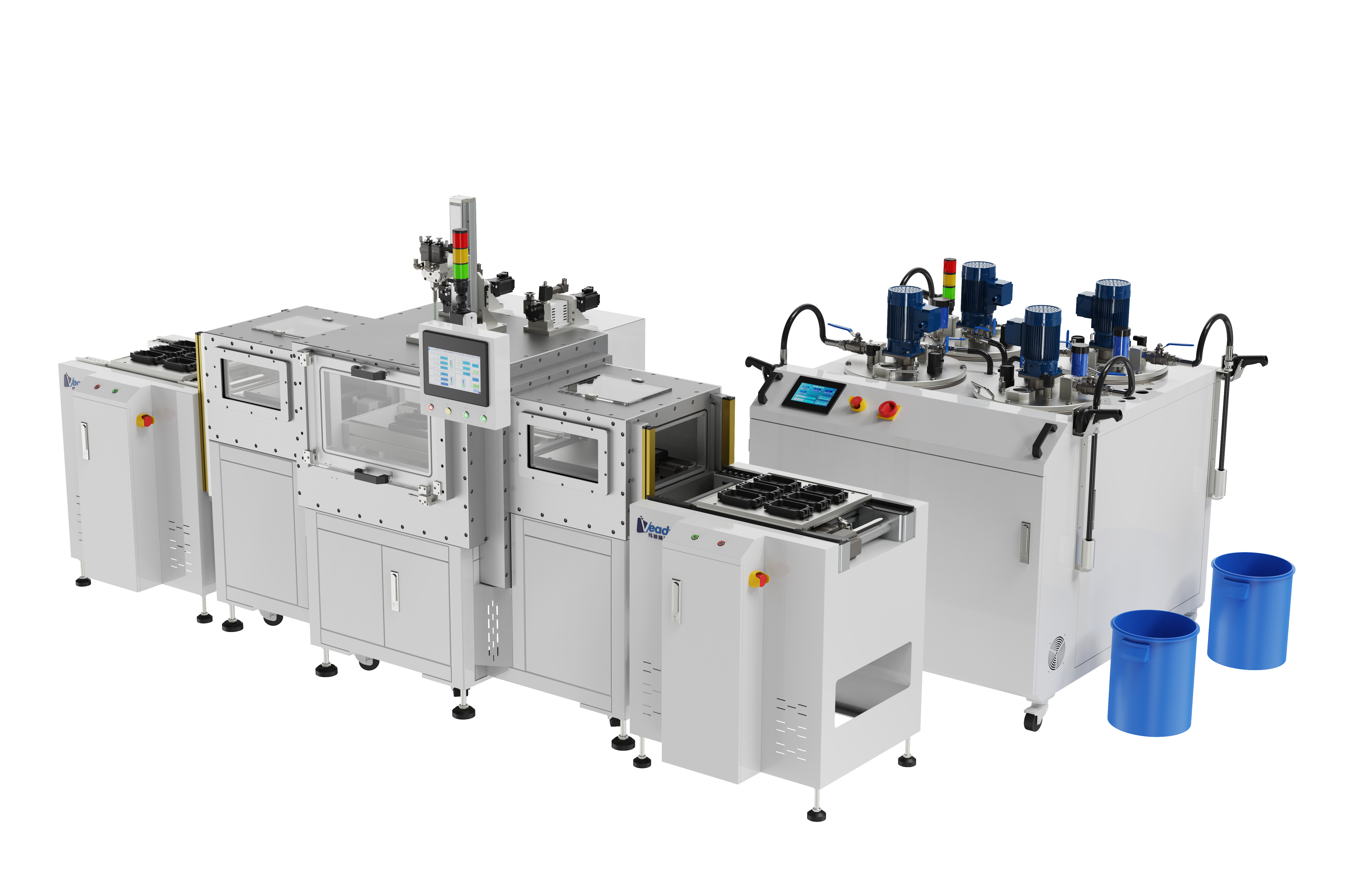

2. The A/B material tank has functions such as heating, stirring, liquid level, defoaming, circulation, and reflux.

3、 The three-axis motion system is paired with independently developed control software.

4、 Realize real-time proportioning, mixing, quantitative vacuum automatic sealing operation of two-component adhesive.

Applicable glue: two-component mixing materials such as epoxy resin, polyurethane, silicon gel, thermal conductive silica gel, and organic encapsulating silica gel.

Application areas: automotive electronics, IGBT modules, capacitors, new energy motors, high-voltage packs, ignition coils, electromagnetic coils, motor stators, sensors, etc.