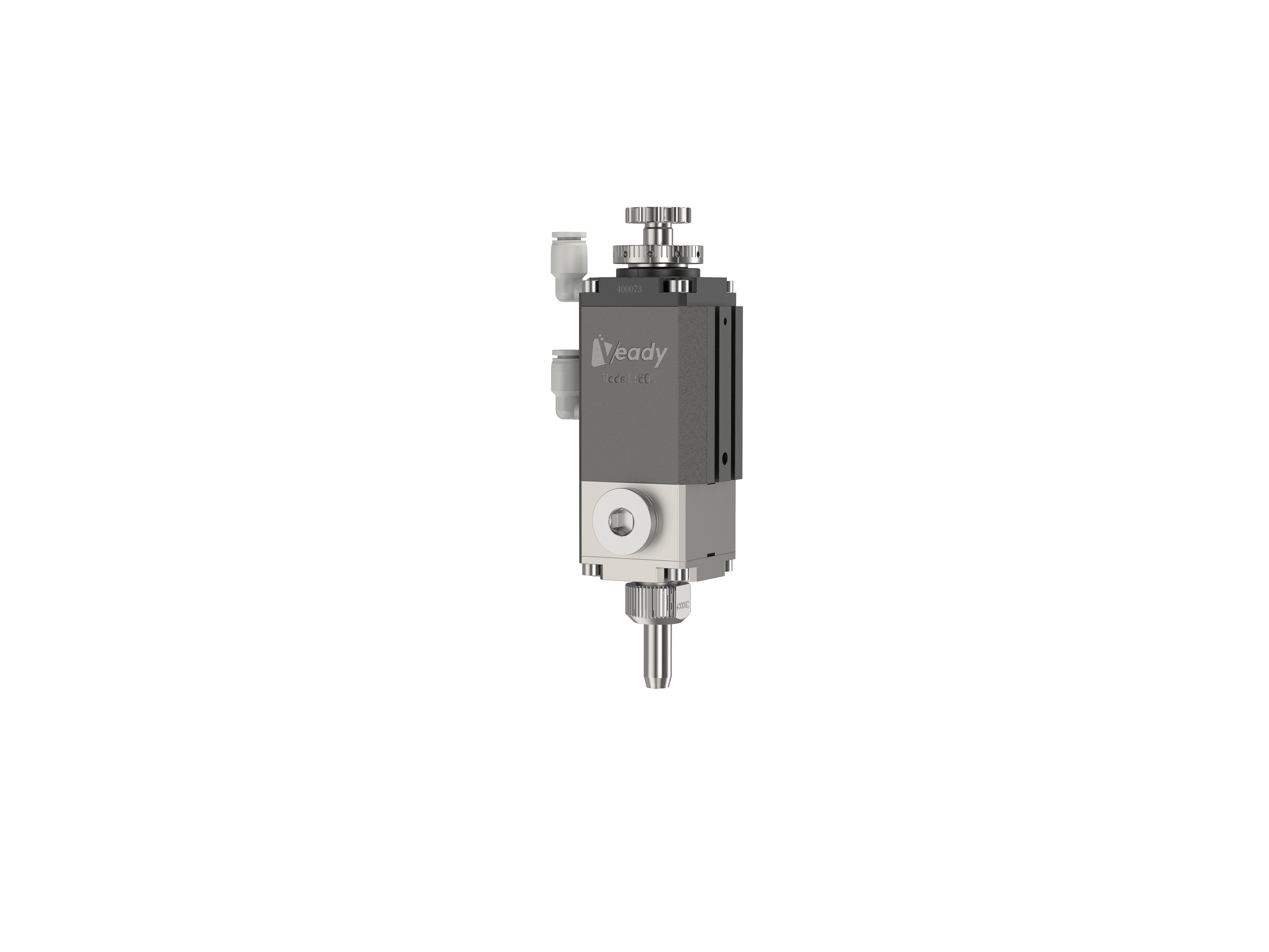

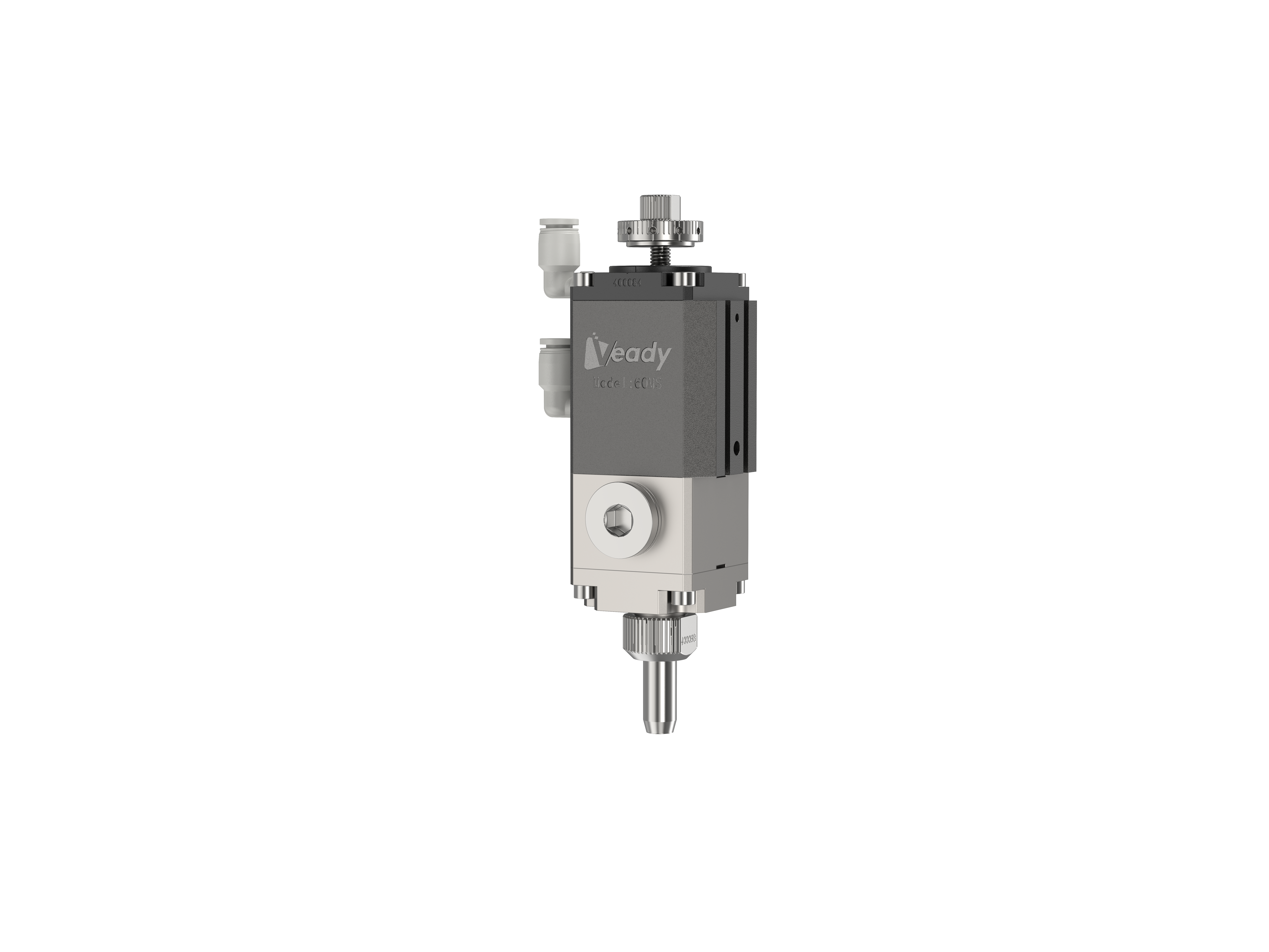

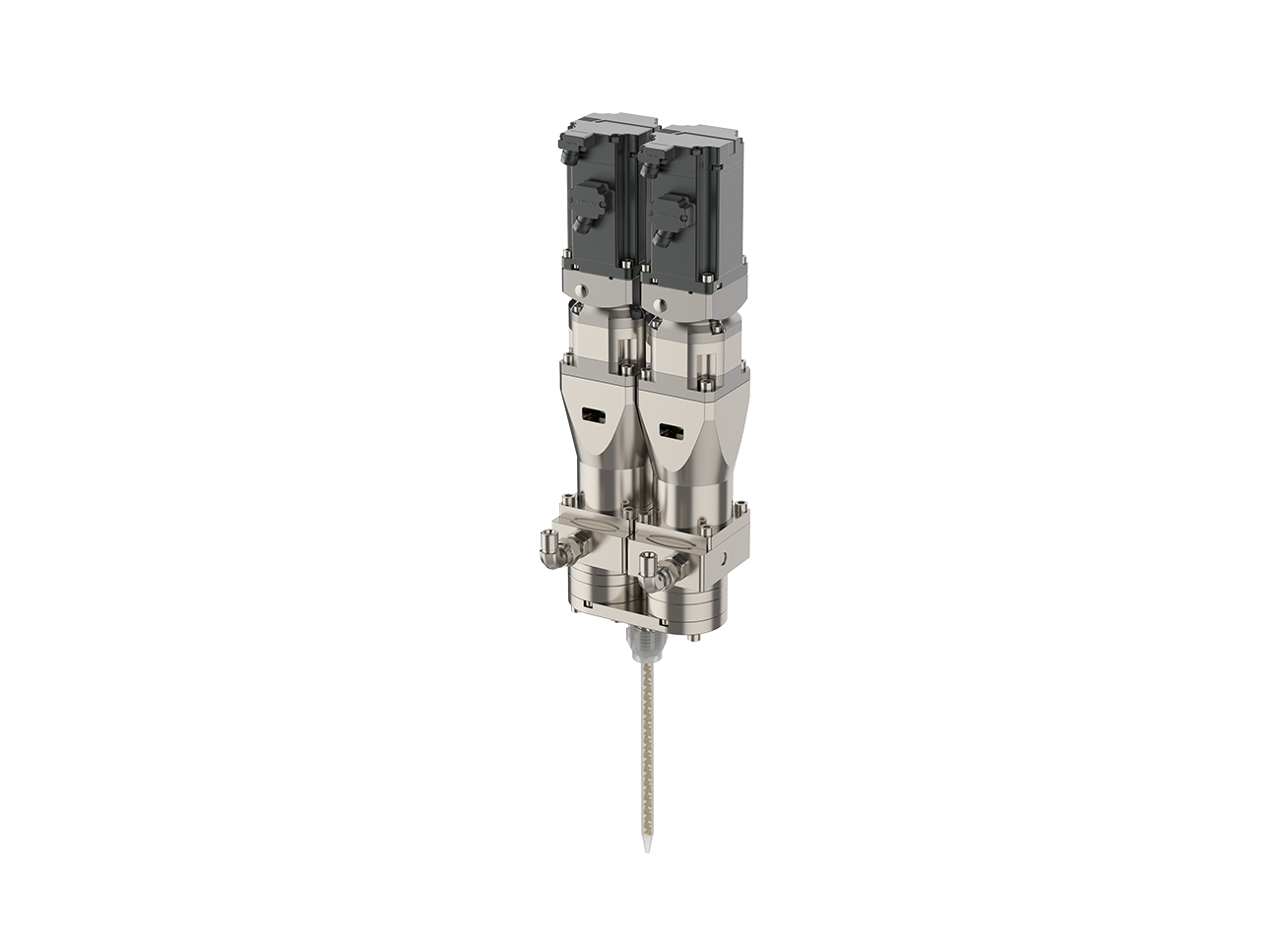

1, for high filler, high viscosity, two-component adhesive, excellent wear resistance.

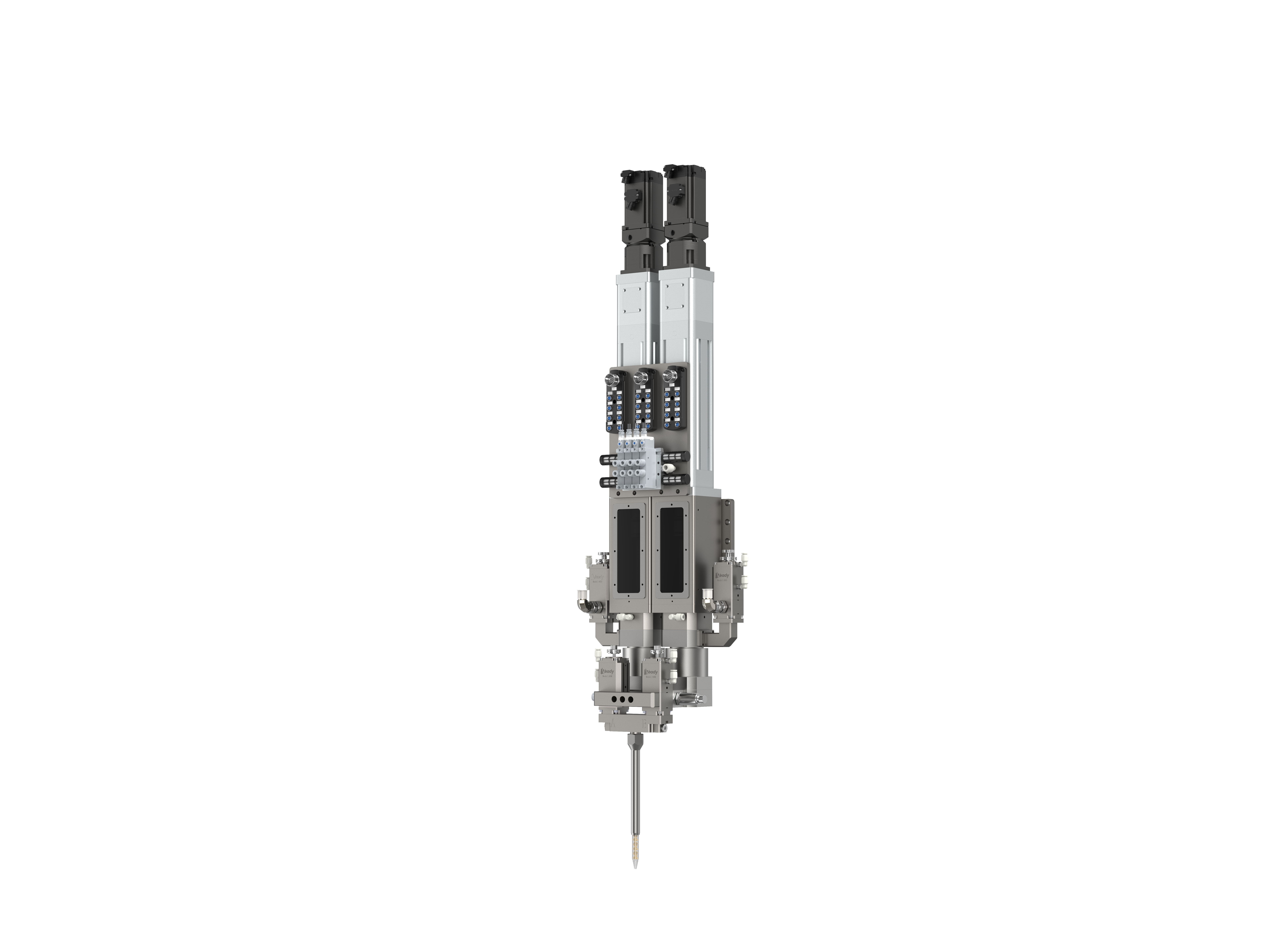

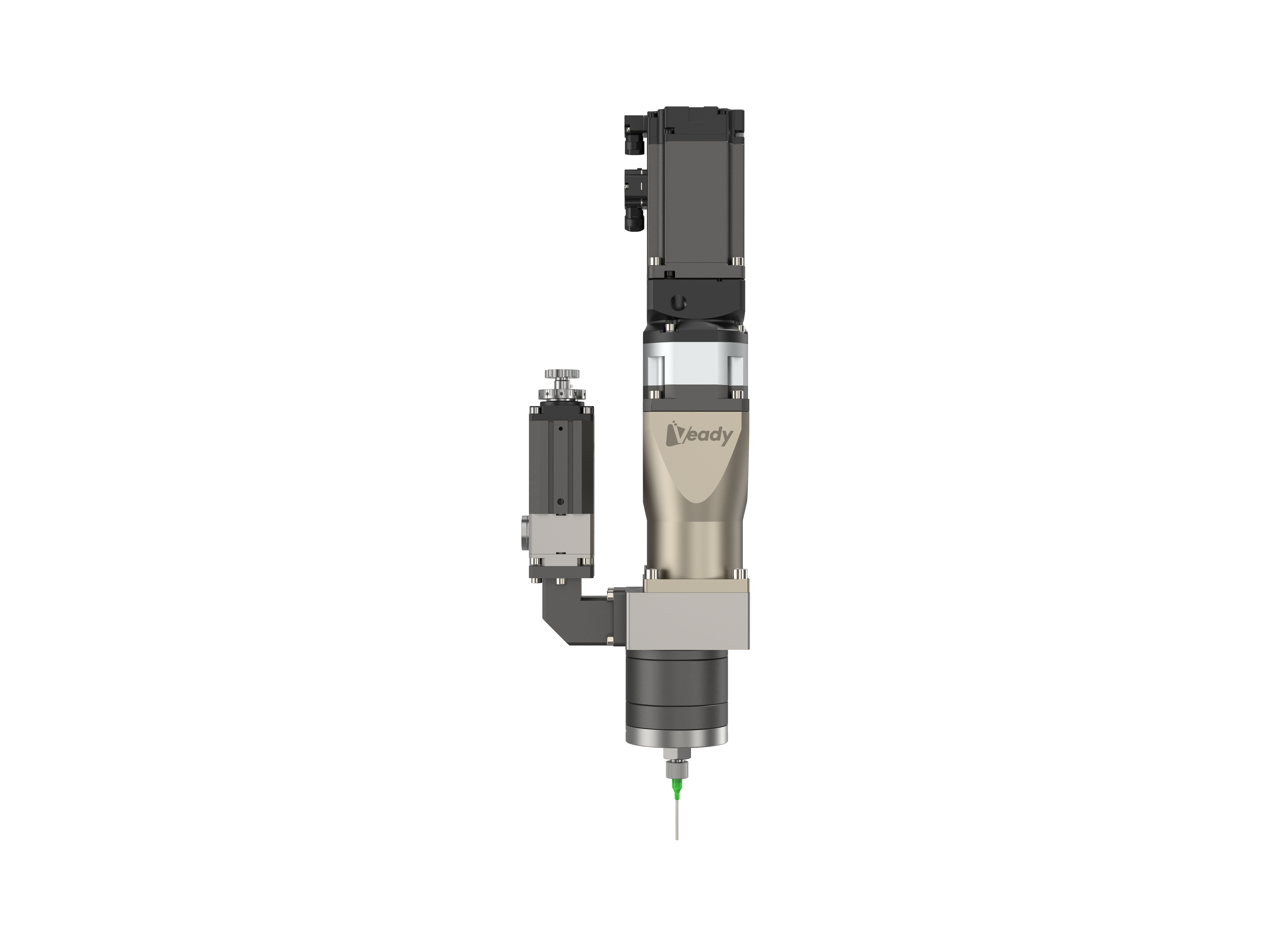

2, modular equipment, simple structure, reduce maintenance time and cost, can be installed in the 6-axis machine hand construction operations.

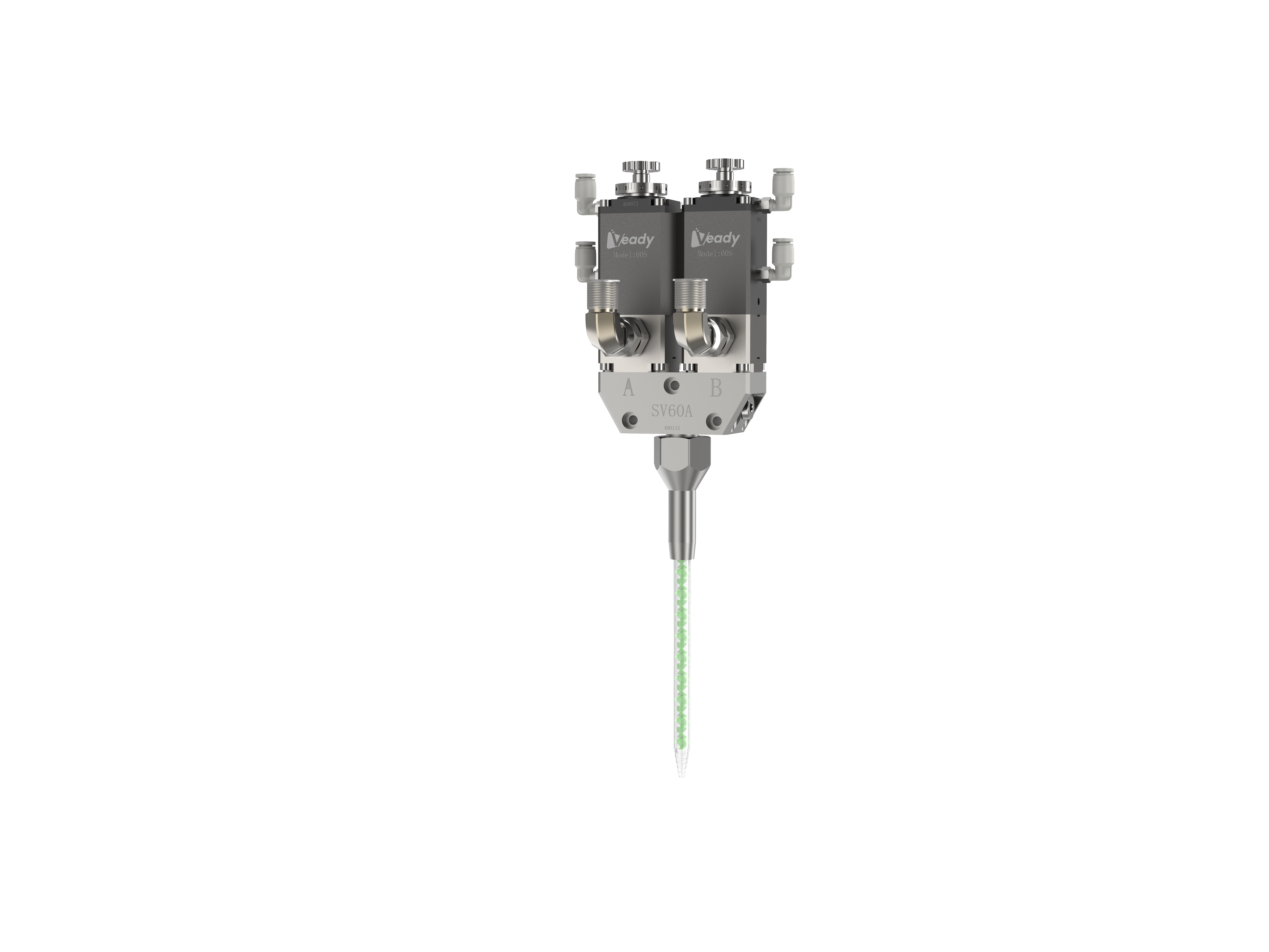

3, docking with MES can realize three-dimensional space path dispensing, precise positioning and glue control, glue valve suction without wire drawing, no leakage.