1、 UV glue dispensing machines are widely used in the industry, promoting the development of intelligent manufacturing

In recent years, with the rapid development of industries such as electronics, optics, and healthcare, UV glue machines have become key equipment in the field of precision manufacturing due to their advantages of fast curing and high-precision dispensing. Its main applications include:

-Electronic packaging: such as PCB board, chip packaging, sensor dispensing, ensuring high adhesive strength and stability.

-Optical lens assembly: used for bonding camera modules and microscope lenses to avoid glue overflow and affect optical performance.

-Medical equipment manufacturing: such as microfluidic chips and medical catheter bonding, to meet the requirements of sterile and high-precision production.

-Automotive electronics: applied to ADAS systems and headlight packaging to enhance shock resistance and sealing.

UV glue technology is gradually replacing traditional heat curing or dual liquid glue processes, becoming the preferred solution for high-end manufacturing.

2、 Working principle of UV glue dispenser

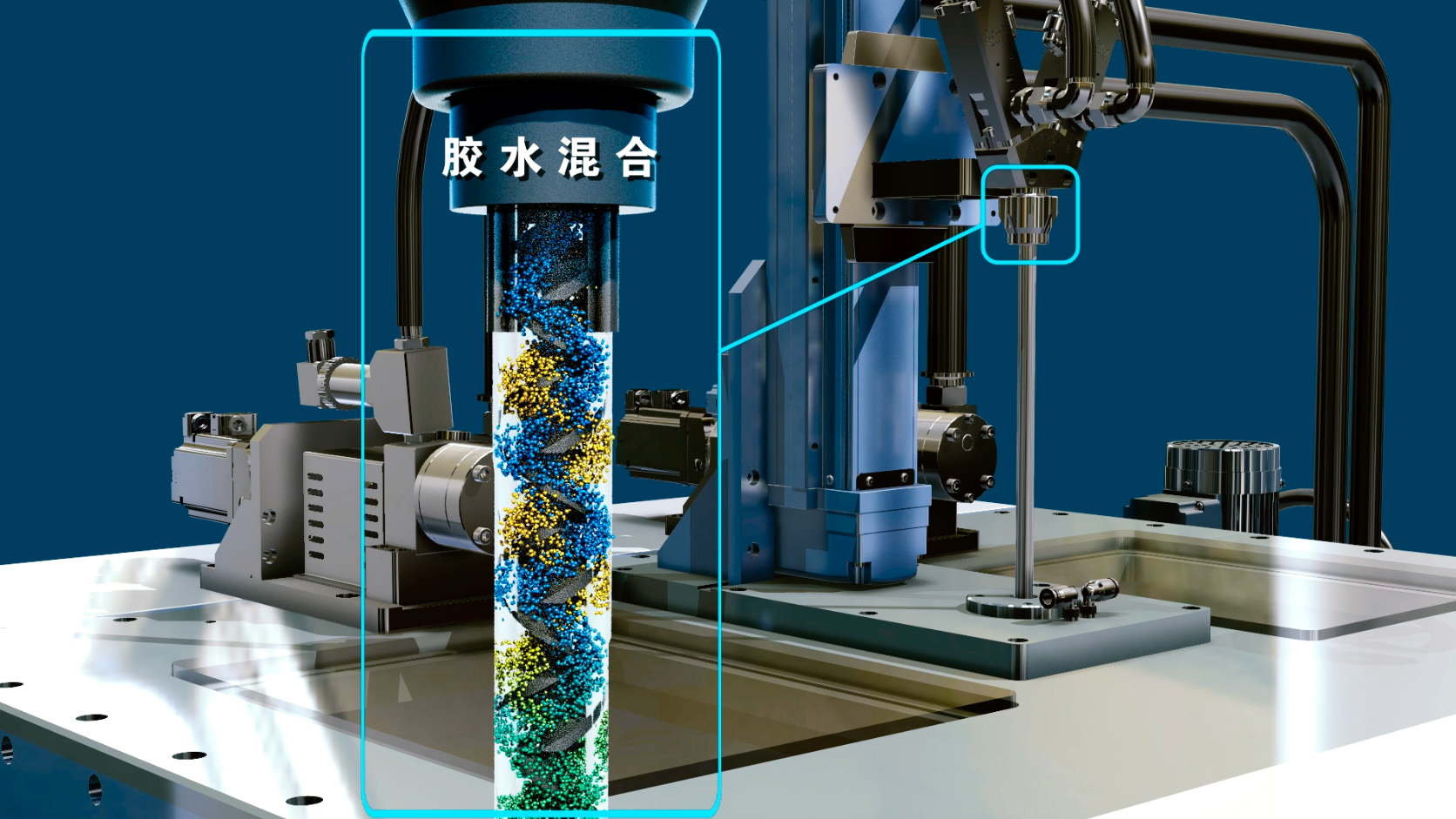

The core advantage of UV glue dispensing machine lies in its UV curing technology, and its working principle is as follows:

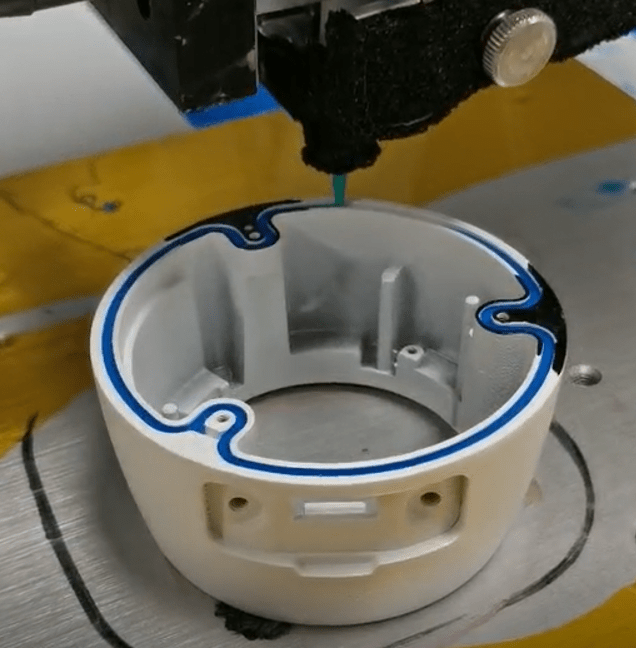

1. Glue dispensing stage: The precision dispensing valve controls the amount of glue to ensure that the glue is accurately applied to the designated position.

2. UV curing stage: UV LED light source (usually wavelength 365nm-405nm) illuminates the glue, triggering a photo initiator reaction to achieve second level curing.

3. Intelligent control: Some high-end models are equipped with visual positioning systems and AI path planning to ensure the accuracy of the dispensing path.

Compared to traditional curing methods, UV glue machines have advantages such as no solvent evaporation, no thermal stress, fast curing speed, and precise control, making them particularly suitable for miniaturized and high-precision manufacturing scenarios.

3、 How to choose a suitable UV glue dispenser?

When choosing a UV glue dispenser, enterprises need to consider the following factors comprehensively:

1. Glue dispensing accuracy: High precision industries (such as semiconductors) require the selection of micro liter level (0.01ml) glue dispensing valves.

2. Curing light source: UV LED light source has a long lifespan, low energy consumption, and is suitable for long-term continuous operation.

3. Adhesive compatibility: UV adhesives of different viscosities need to be matched (such as spray valves for low viscosity adhesives and screw valves for high viscosity adhesives).

4. Automation level: Equipment with CCD visual positioning and mechanical arm linkage function can improve production efficiency.

4、 Weidi Glue Dispensing Machine: Innovative Technology Empowers Intelligent Manufacturing

As a leading supplier of dispensing equipment in the industry, Veady's UV dispensing machine series is highly favored by the market due to its high precision, stability, and intelligence

✅ Ultra high precision dispensing: using imported piezoelectric ceramic valves, the minimum dispensing volume can reach 0.01ml, suitable for microelectronic packaging.

✅ Intelligent UV curing system: Customized UV light source, adjustable curing time (0.1s-10s), suitable for different adhesive needs.

✅ Automation integration solution: supports linkage of robotic arms, visual positioning, and seamless integration with SMT production lines.

✅ Energy saving and environmental protection: UV LED light source has a lifespan of over 20000 hours, which is 70% more energy-efficient than traditional mercury lamps.

Weidi dispensing machines have been successfully applied in multiple fields such as consumer electronics, automotive electronics, medical equipment, etc., helping enterprises improve production efficiency and product yield.

5、 Looking ahead to the future: Continuous innovation in UV dispensing technology

With the rise of emerging industries such as 5G communication, Mini LED, AR/VR, UV glue machines will develop towards higher precision and intelligence. Weidi will continue to invest in research and development, promote the upgrading of dispensing technology, and provide more efficient solutions for the global manufacturing industry.