CIPG and FIPG sealing dispensing process

CIPG (Cured In-Place Gasket) and FIPG (Formed-In-Place Gasket) are two different liquid sealing processes, the main difference between them is the curing timing of the sealant and the way it is handled.

CIPG process: The liquid sealant is coated on the surface of the substrate by an automated dispensing equipment, and then the silicone is cured by heating or other means. The cured silica gel is mechanically locked (i.e. compressed) to achieve seal protection.

This process can directly replace the traditional pre-formed gaskets, reduce labor costs, and can be accurately positioned to avoid manual installation caused by deviation, thereby improving the product pass rate.

One of the features of the CIPG process is that it can be disassembled at any time, which is very advantageous for parts that require frequent rework.

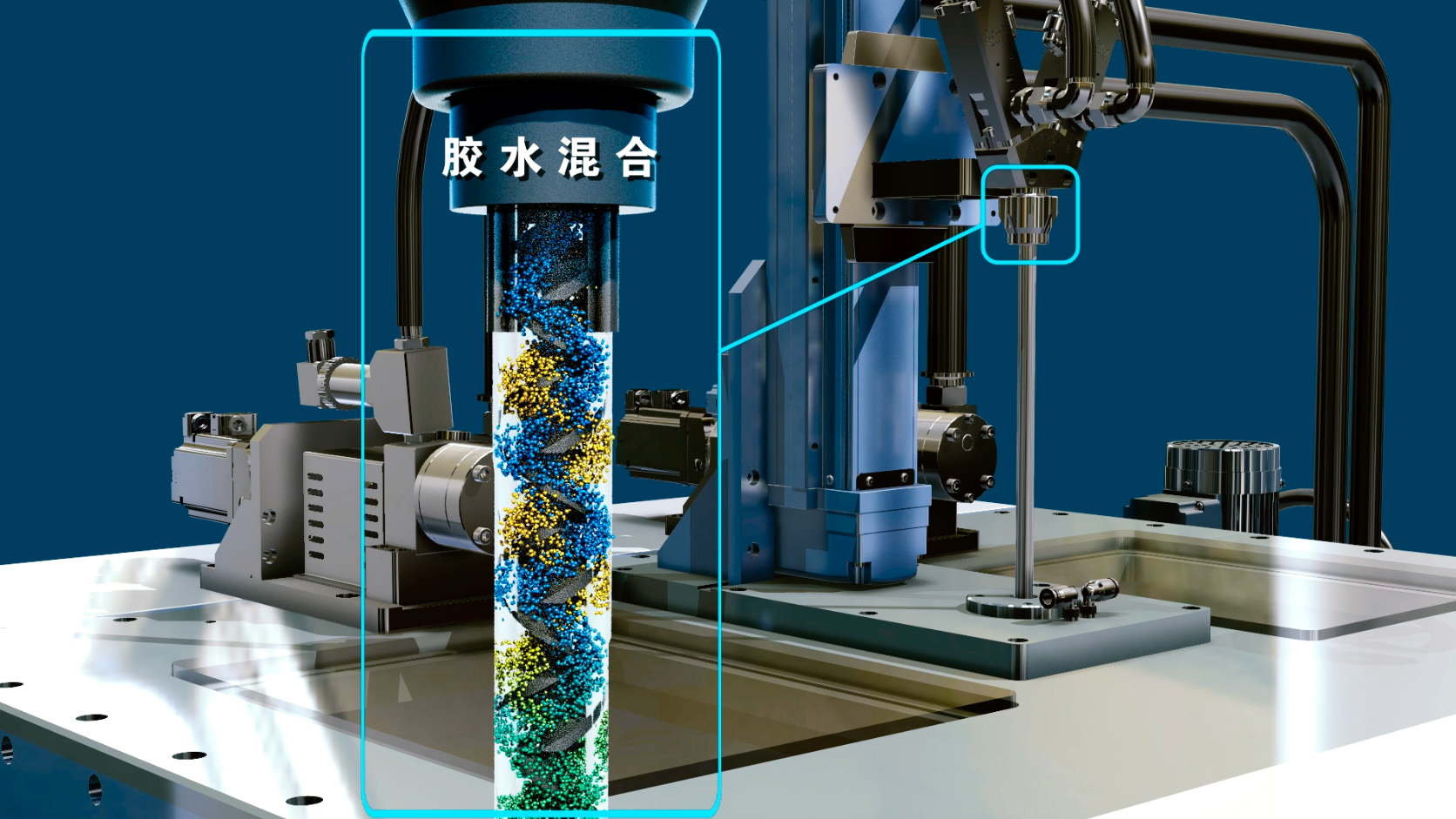

FIPG process: The workpiece is assembled in the uncured state of the liquid sealant, and then placed for a period of time to allow the sealant to fully cure. This way through the glue bonding to achieve the role of sealing protection.

The process gradually replaces the traditional mechanical joint technology, such as riveting, welding, screw fastening, etc., convenient construction, automatic dispensing reduces labor costs.

The use of FIPG reduces the use of metal assembly parts, reduces the weight of the final product, and the excellent properties of the organic silicone adhesive are enough to evenly distribute the stress caused by the component size deviation, reducing the risk of local stress overload.

In summary, the main difference between CIPG and FIPG is that CIPG emphasizes the dry assembly method, that is, the glue is first applied to cure and then assembled, while FIPG emphasizes the wet assembly method, that is, the assembly is first applied to cure and then cured. The two processes have their own characteristics and are suitable for different sealing needs.