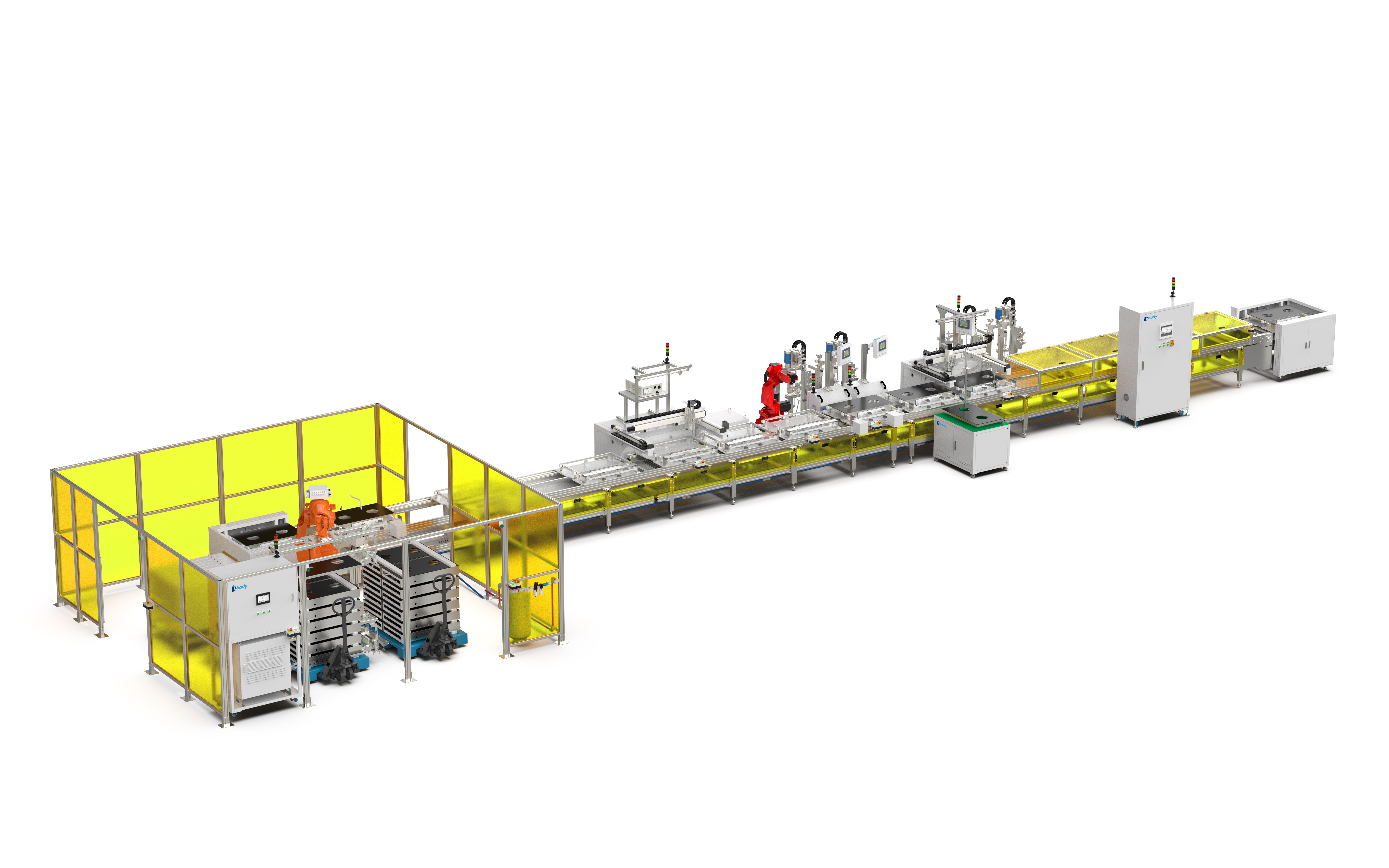

Standard modular design of the whole line, strong compatibility, suitable for automatic production of multi-specification products

Can realize product loading and unloading, coating, detection, curing, vehicle transmission integrated operation

High-precision wear-resistant metering pump, stable and accurate rubber

Can be configured with A/B static valve, dynamic valve, screw valve, piston valve and other two-component valve body applications

01

1、Automatic glue one-stop solution to ensure quality, reduce labor and improve efficiency.

2、Industrial PC/PLC control, with scanning, MES data acquisition and communication functions.

3、Self-developed software system, free upgrade service.

4、According to glue characteristics, gear pump, screw pump, plunger pump and diaphragm pump can be configured for material preparation system.

5、Rubber barrel is made of SUS304 stainless steel, corrosion resistant. Double barrel design, sealed storage, not easy to deteriorate, capacity 10L, 20L, 45L, 60L optional.

6、The rubber barrel is equipped with constant temperature heating, motor stirring, vacuum degassing, liquid level sensor, pipeline pressure monitoring and other functions, abnormal alarm and interface prompt.

Applicable glue: epoxy resin, polyurethane, organic silicone and other two-component glue

Applications: kitchen appliances, OBC charging module, automotive electronics and other industries.

02

| device name | Automatic gluing production line (gluing station parameters) |

| device model | custom |

| effective stroke | X=500*Y=500*Z=100mm |

| mechanical precision | ±0.02mm |

| Barrel specifications | Reagent A 30L+ Reagent B 30L |

| proportional accuracy | ≤±3% |

| the plastic precision | ≤±3% |

| glue speed | 1-5g/s |

| working power supply | AC380V、50Hz、4.5KW |

| Working gas source | 0.5-0.7MPaA |

| Outline size | L1500*W1300*H1850 |

| equipment weight | Approximately 450KG |