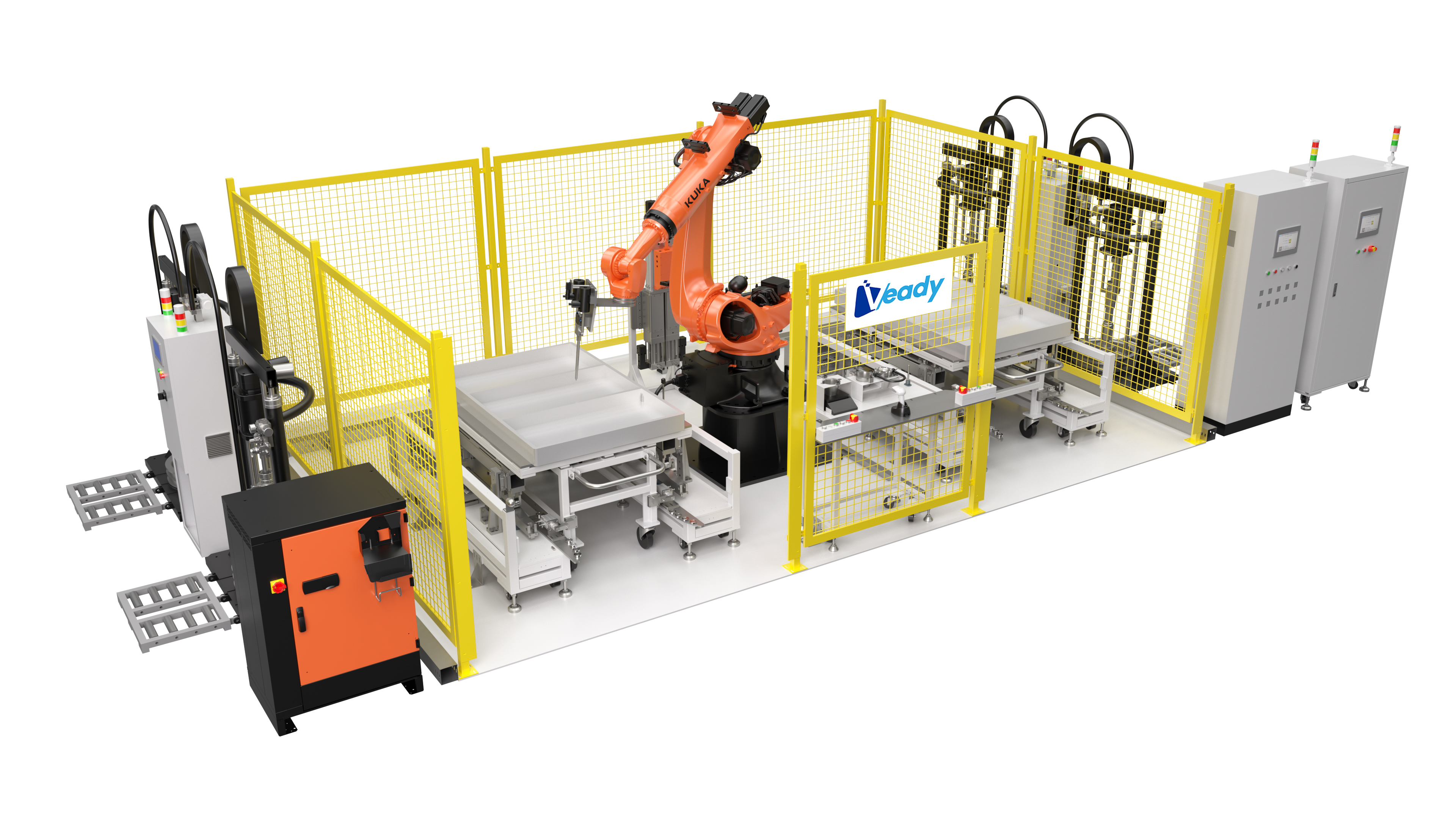

1、It is composed of 55 gallon platen, one standby and one glue pump, variable ratio metering machine, six axis robot and cart positioning mechanism.

2、Optional: flow meter, automatic needle alignment, visual positioning, nozzle cleaning, 3D rubber detection and other functional modules.

3、Configuration: 250cc, 400cc, 550cc, 950cc displacement quantitative machine, static mixing mode glue.

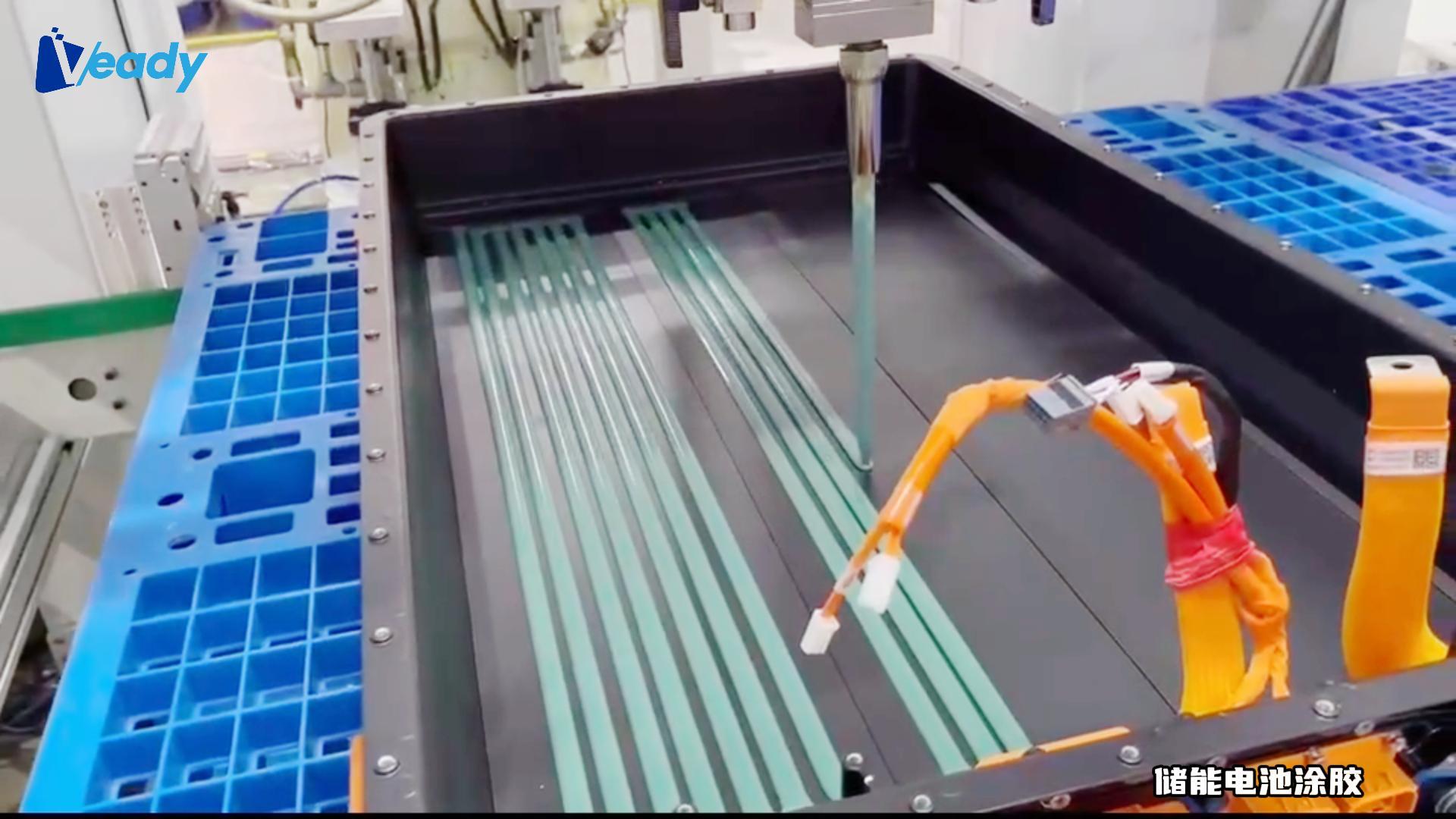

Applicable glue: two-component thermal conductive adhesive, sealant, structural adhesive and other two-liquid materials.

Application: Power battery, energy storage battery, PACK box, cell module, solar photovoltaic coating.