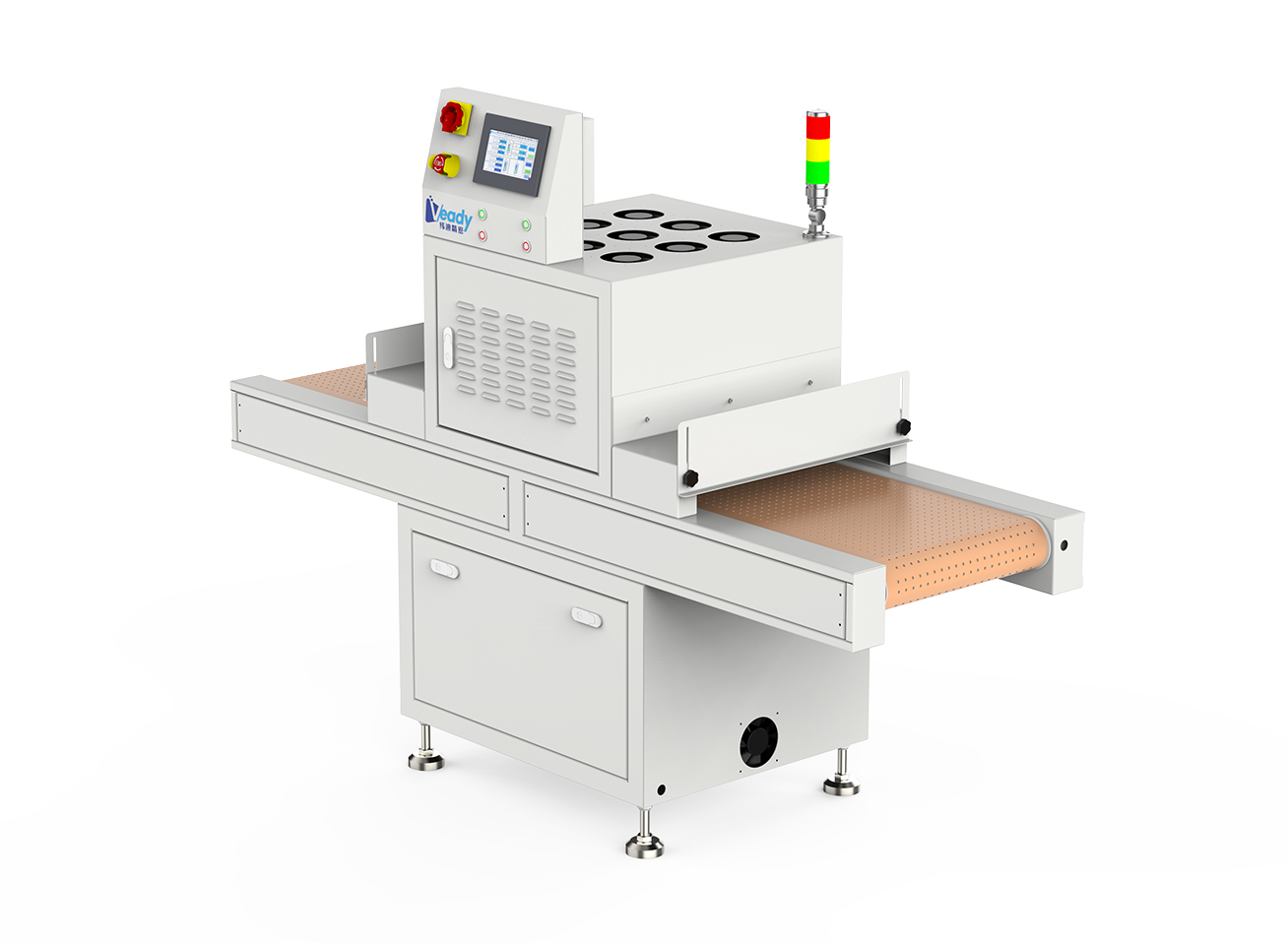

1. The whole machine adopts PLC+HMI human-machine interface, which is easy to operate and can set the operation management authority level.

2. The Control System has a variety of communication ports and protocols to facilitate communication with the host computer, and the equipment can run automatically on a stand-alone or online basis.

3. The protection device has PID self-tuning and has the functions of timed alarm and power-off, over-temperature power-off and leakage protection after the temperature reaches.

4. Using intelligent temperature controller, PID intelligent calculation, and SSR solid state relay output, the temperature can be accurately controlled.

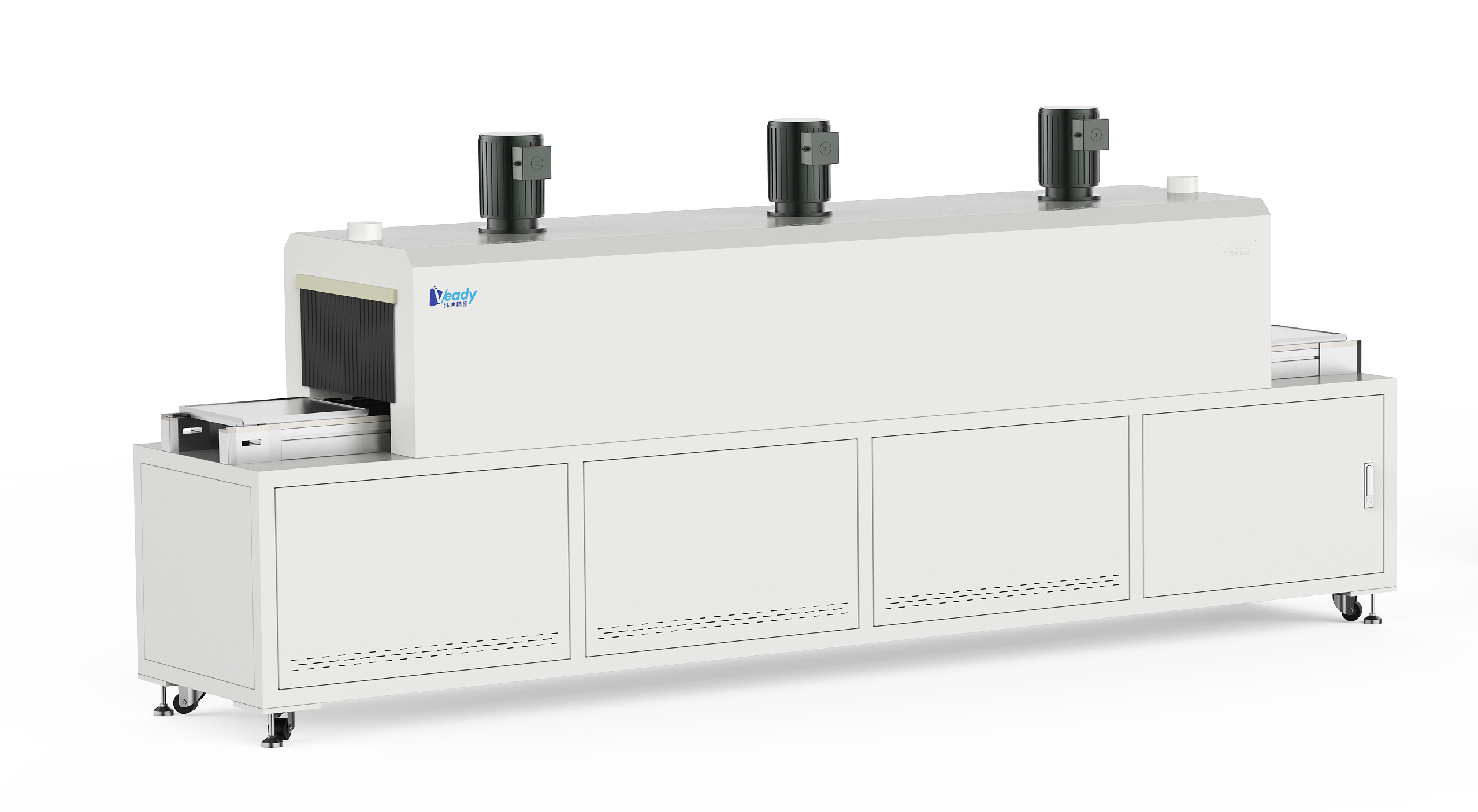

5. The conveyor belt adopts double-speed Chains, and the products are placed on special pallets and run in a cycle.

6. The temperature of the equipment shell is low and does not affect the indoor ambient temperature and operators.

Application areas: product glue filling, preheating and curing, product baking, drying, preheating, curing, aging, etc.