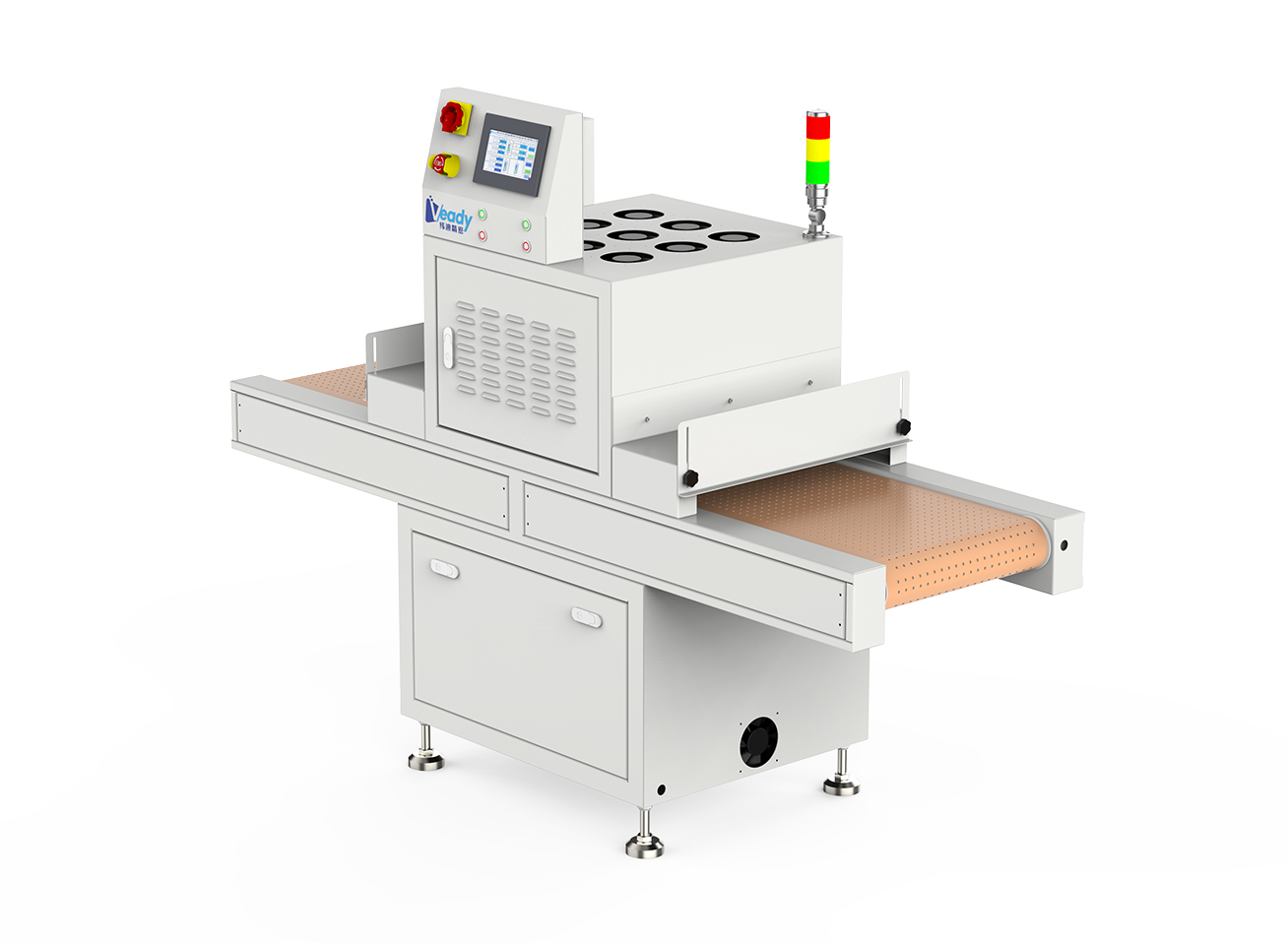

1. The curing machine is equipped with two sets of Air Cooling UVLED cold light sources.

2. Equipped with a special heat dissipation device to ensure that the operating temperature on the surface of the equipment is lower than 50°.

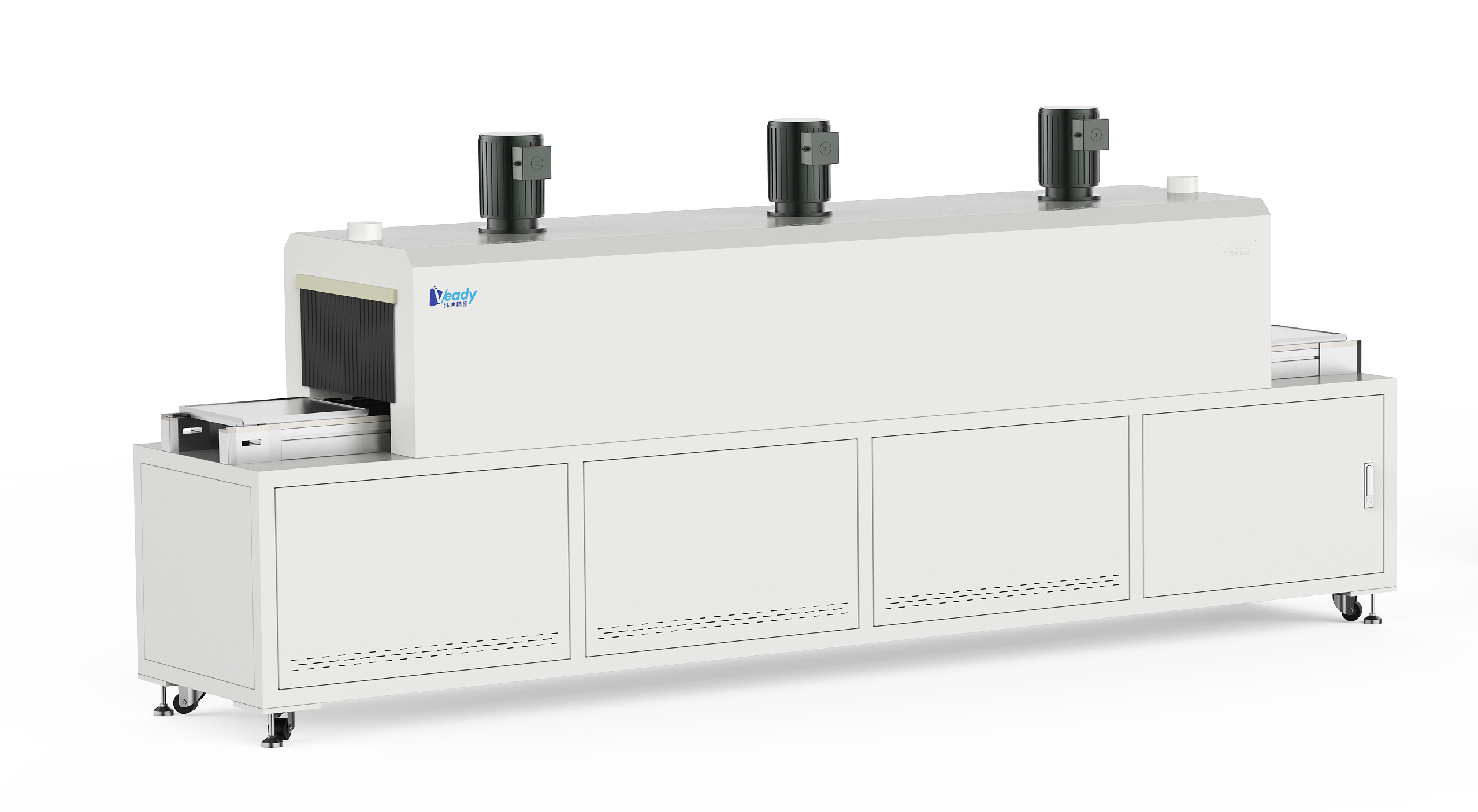

3. The width of the conveyor belt is 450mm, and the line speed is adjustable within 3m/min.

4. LED lamp beads are equipped with short circuit, overcurrent, overtemperature and other protection functions.

6. Light Source Power can be set independently and displayed in percentage, and the power adjustment accuracy can reach 1%.

7. It has automatic, manual, step, pulse and other irradiation modes.

8. Equipped with a complete external I/O control interface to connect to automation equipment.

9. Touch operation panel, simple and intuitive operation.

10. It adopts the conveying left-in and right-out method, which has strong compatibility.

Application fields: Touch screen TP curing, medical device bonding and curing, mobile phone screens, tablet computers, wire harness connectors, LCD screens, etc. UV glue bonding and curing.