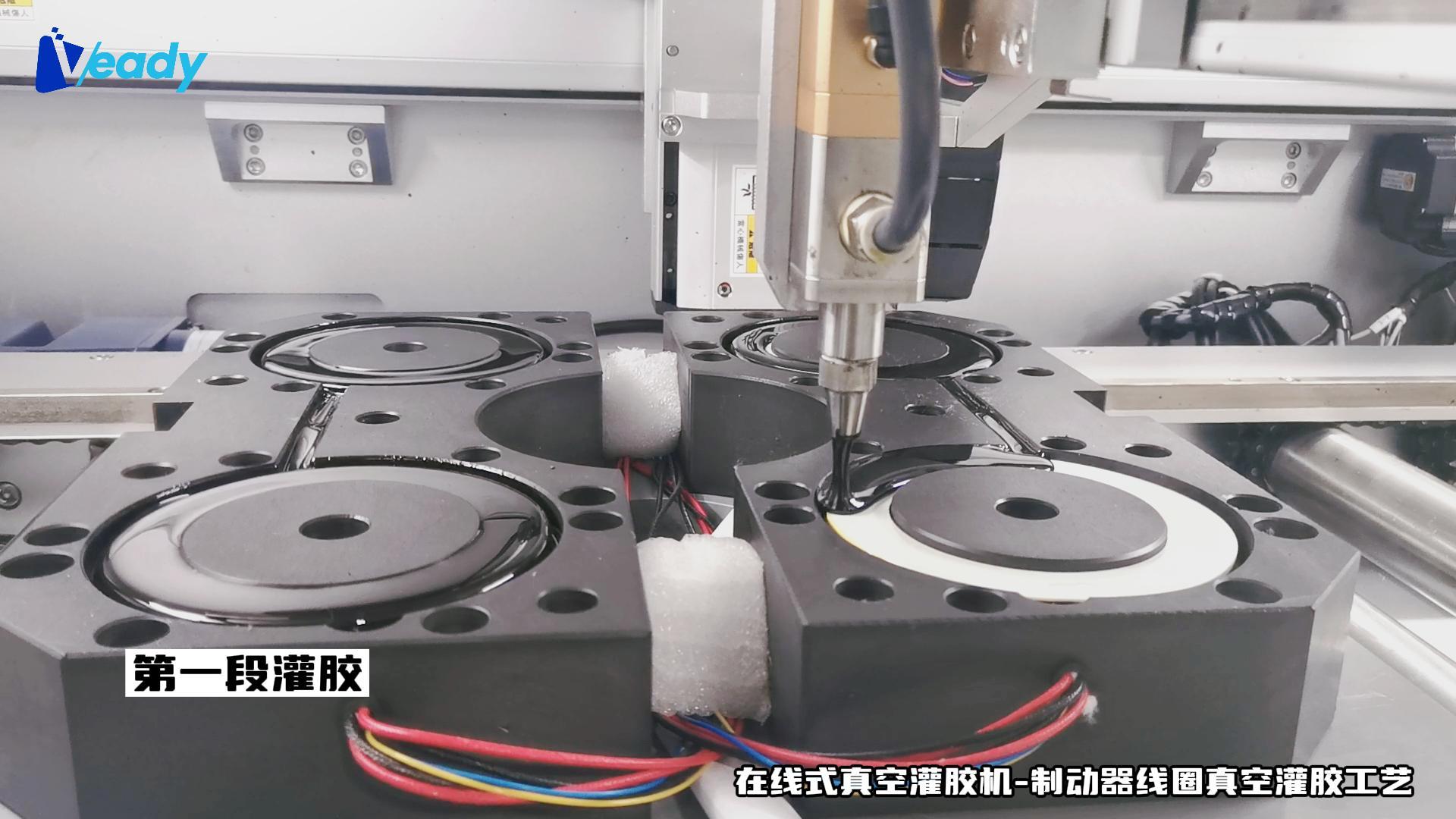

1. Bottom lifting three-axis running module, realize point to point, straight line, shaped, arc interpolation and other graphic trajectory gluing.

2. Independent research and development software system, realize two-component glue instant proportioning, instant mixing, instant filling operation.

3. System supports all kinds of communication, MES system data acquisition, easy to learn and understand.

4. Can store 100 groups of process program files, without reprogramming.

5. Size of glue output, speed of glue output, time of glue output and stopping time can be parameterized.

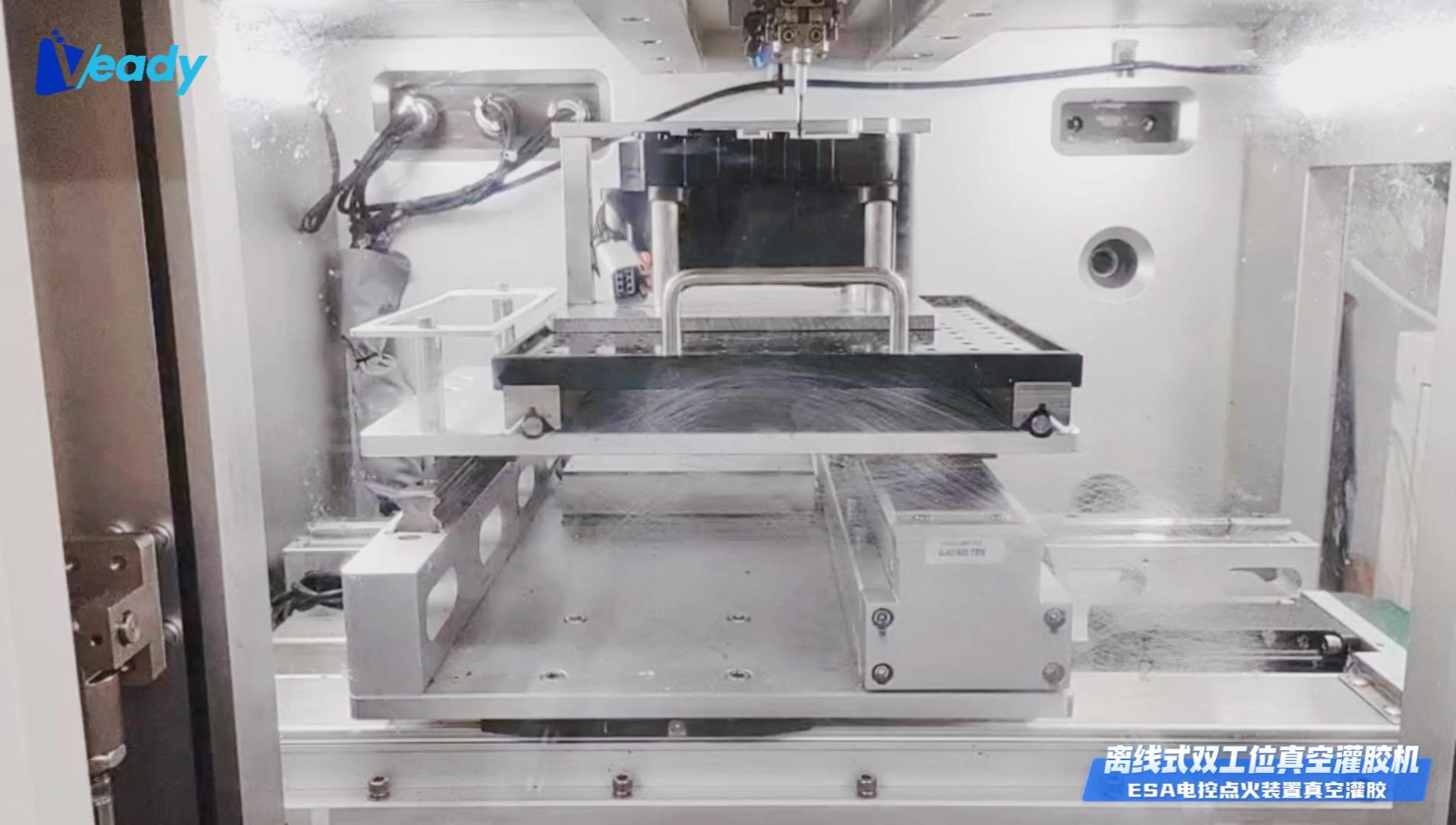

6. Vacuum chamber adopts automatic lifting door or manual switching door, equipped with safety grating, safe and reliable use.

7. Vacuum chamber is equipped with vacuum pump of famous brand, suction flow 100-300m³/h.

8. Vacuum sensor can be adjusted arbitrarily, the vacuum pump stops working automatically after the vacuum reaches the upper limit value.

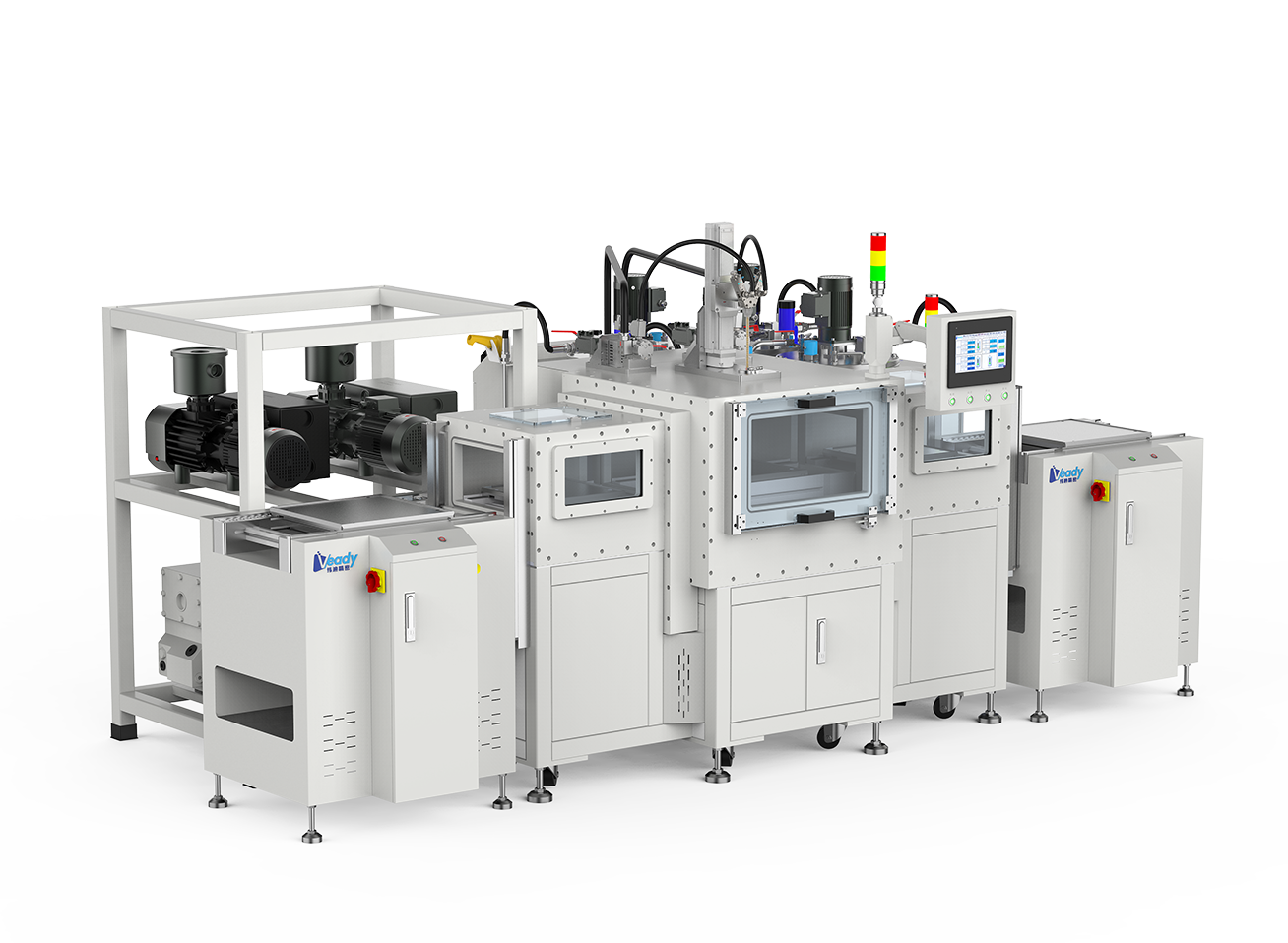

9. According to the characteristics of the glue, the preparation system can be configured with gear pumps, screw pumps, plunger pumps, diaphragm pumps for feeding.

10. Glue barrel is made of SUS304 stainless steel, corrosion-resistant. Double barrel design, sealed preservation, not easy to deteriorate, capacity 10L, 20L, 45L, 60L optional.

11. The glue barrel is equipped with constant temperature heating, motor stirring, vacuum defoaming, liquid level sensor, pipeline pressure monitoring and other functions, with abnormal alarm and interface prompts.

Applicable glue: epoxy resin, polyurethane, thermally conductive silicone, organic potting silicone and other two-component proportioning mixed materials.

Application areas: automotive electronics, capacitors, new energy motors, high voltage packages, ignition coils, electromagnetic coils, motor stators, sensors, etc.