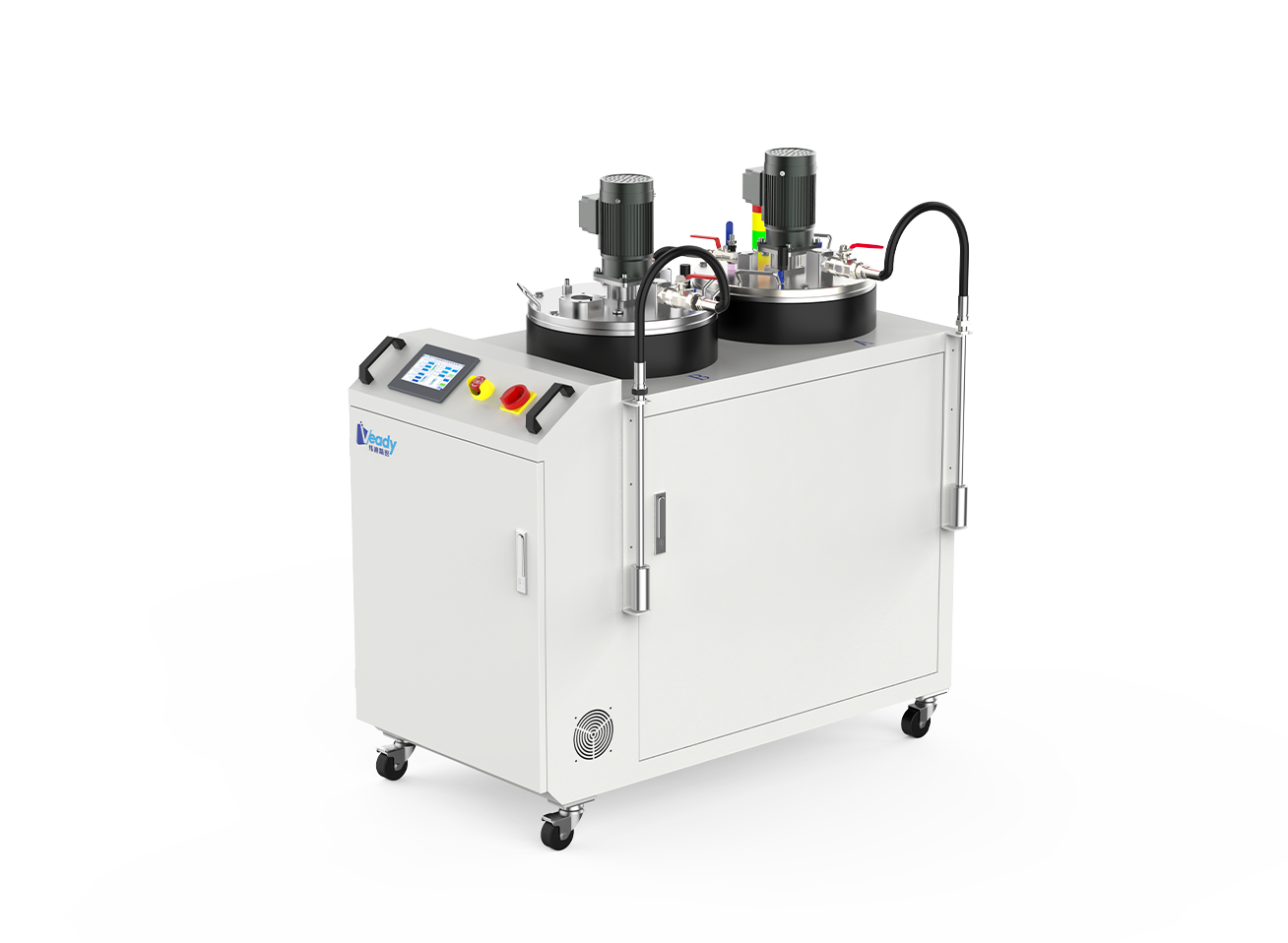

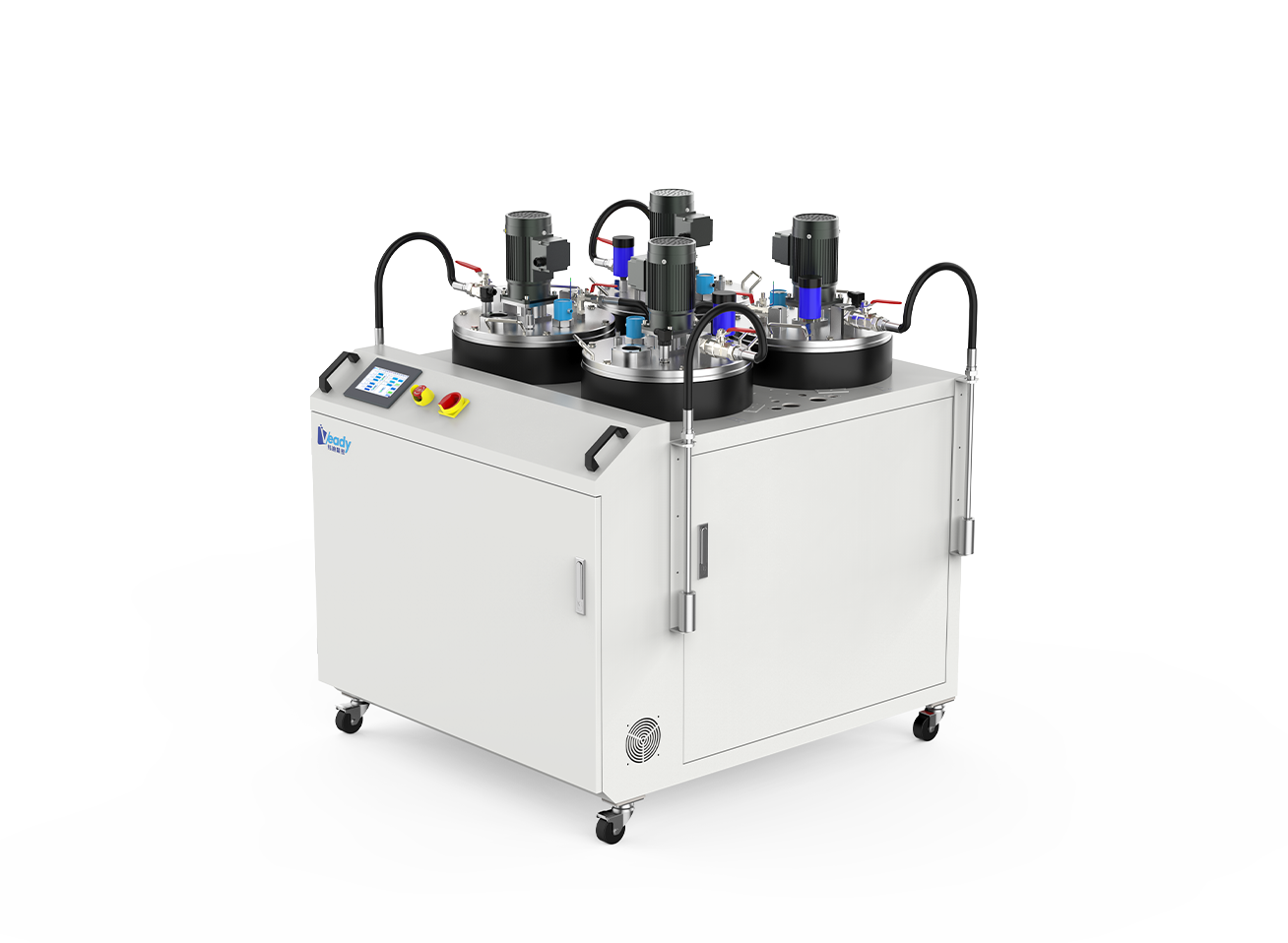

1. Double electric screw pressure plate feeding, suitable for high viscosity glue supply operations.

2. It is equipped with low liquid level alarm, and optional flow meter and glue path detection module.

3. The modular design of the equipment facilitates daily maintenance by customers.

4. Depending on the glue requirements, a 5-gallon or 55-gallon Platen Pump can be selected.

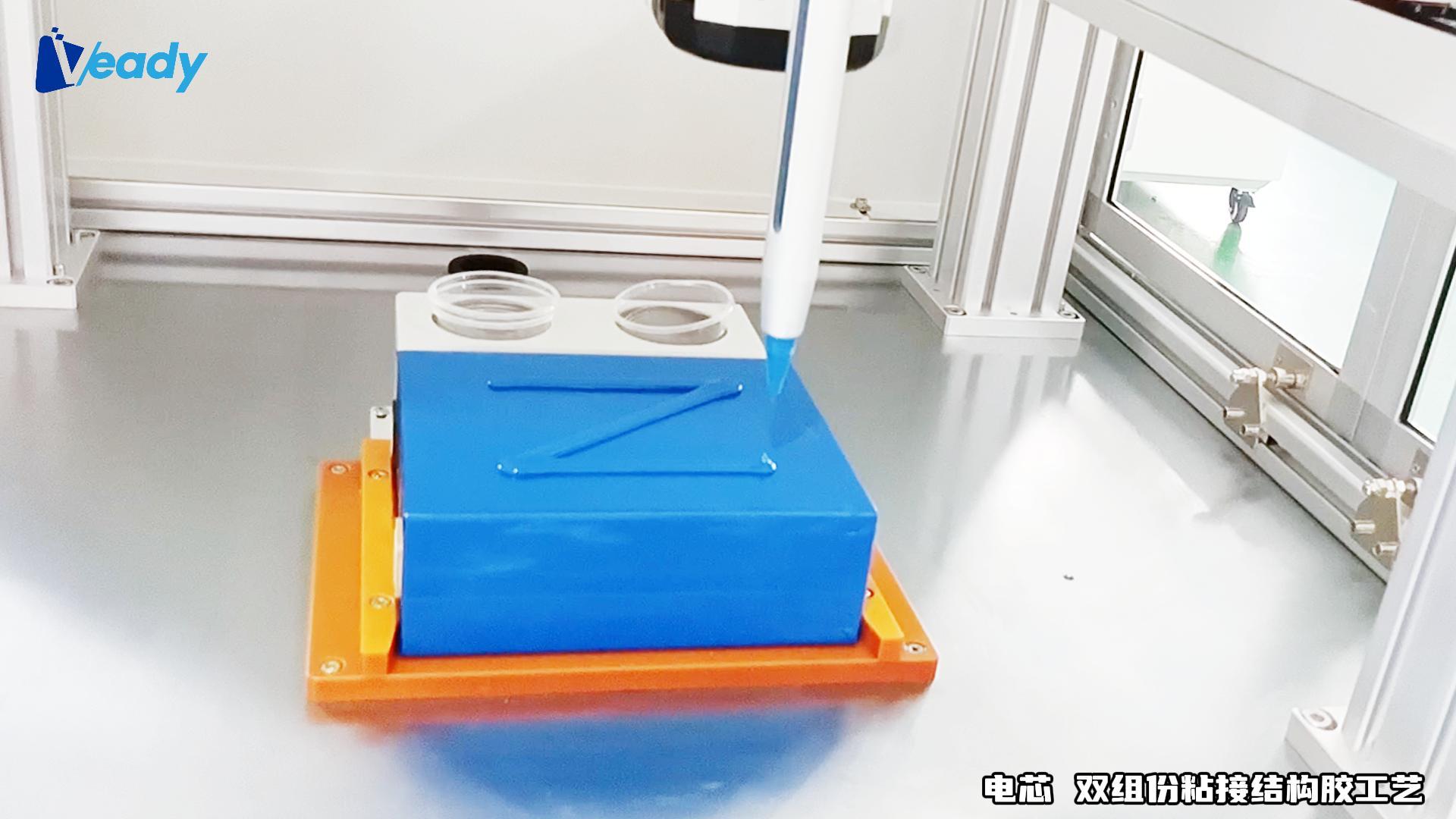

Applicable glue: two-component thermally conductive glue, sealant, structural glue and other two-liquid materials.

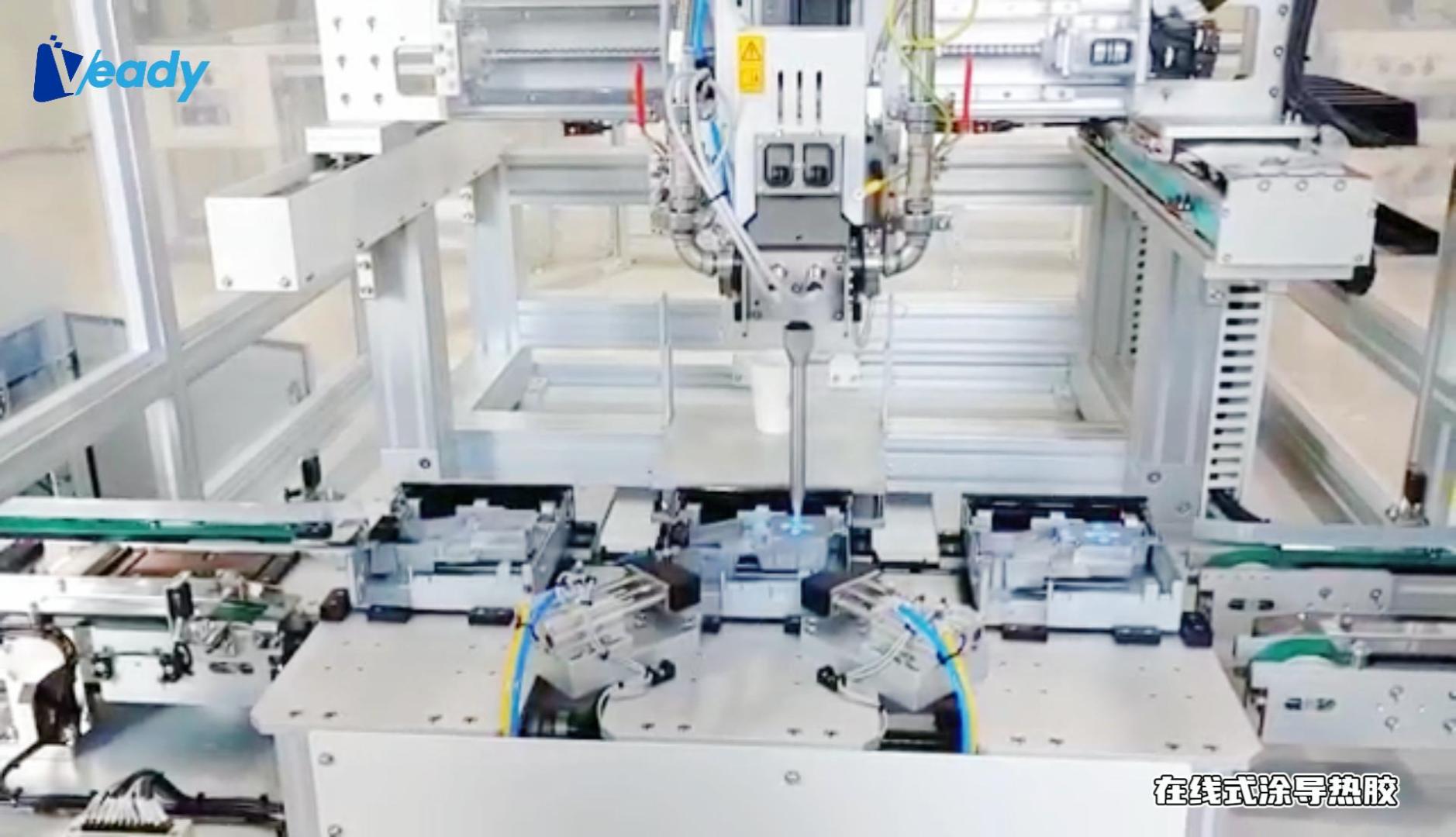

Application fields: Glue coating on controllers, home appliances, power tools, photovoltaic panels, ECU, OBC, CDU auto parts, etc.