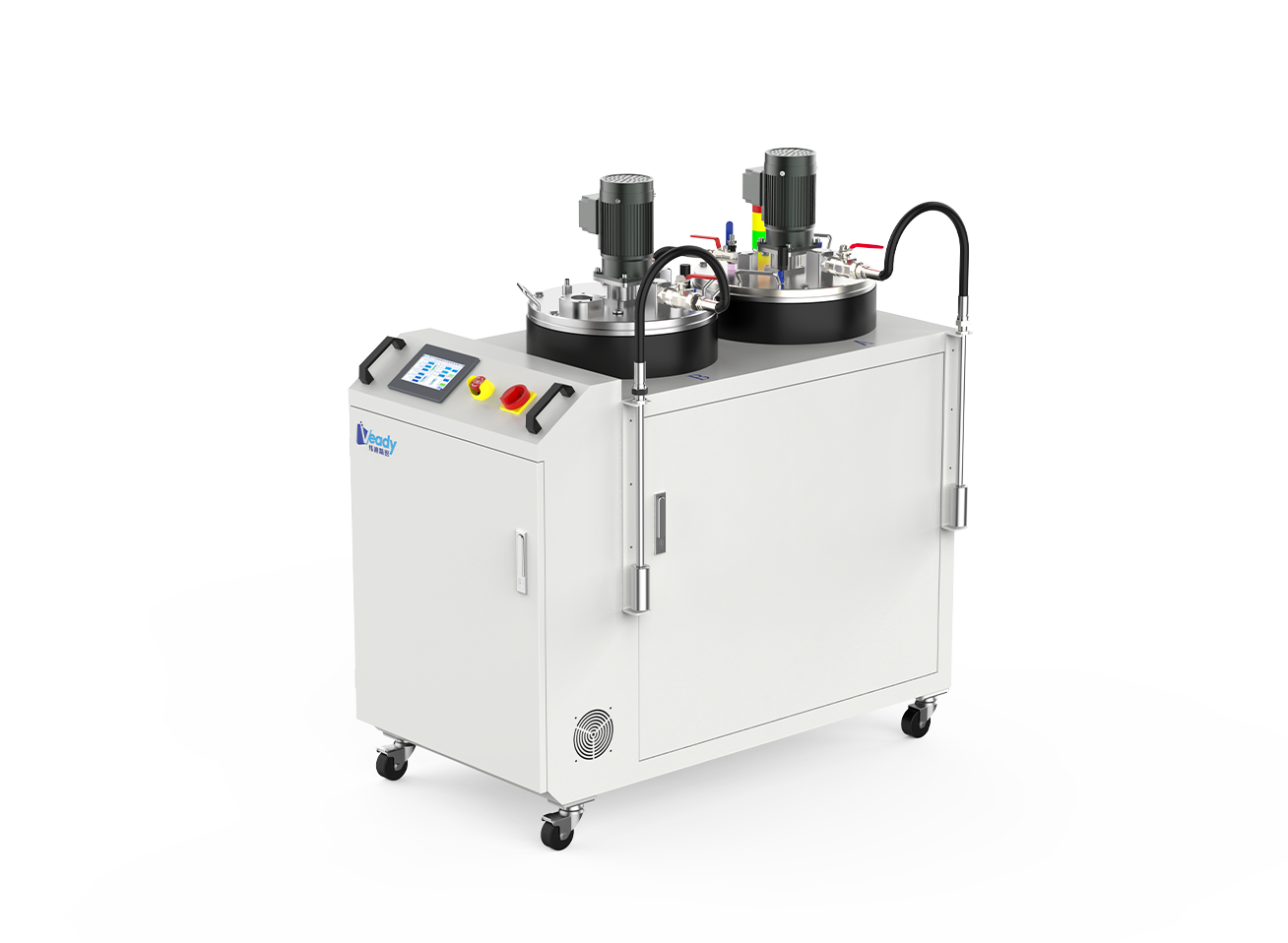

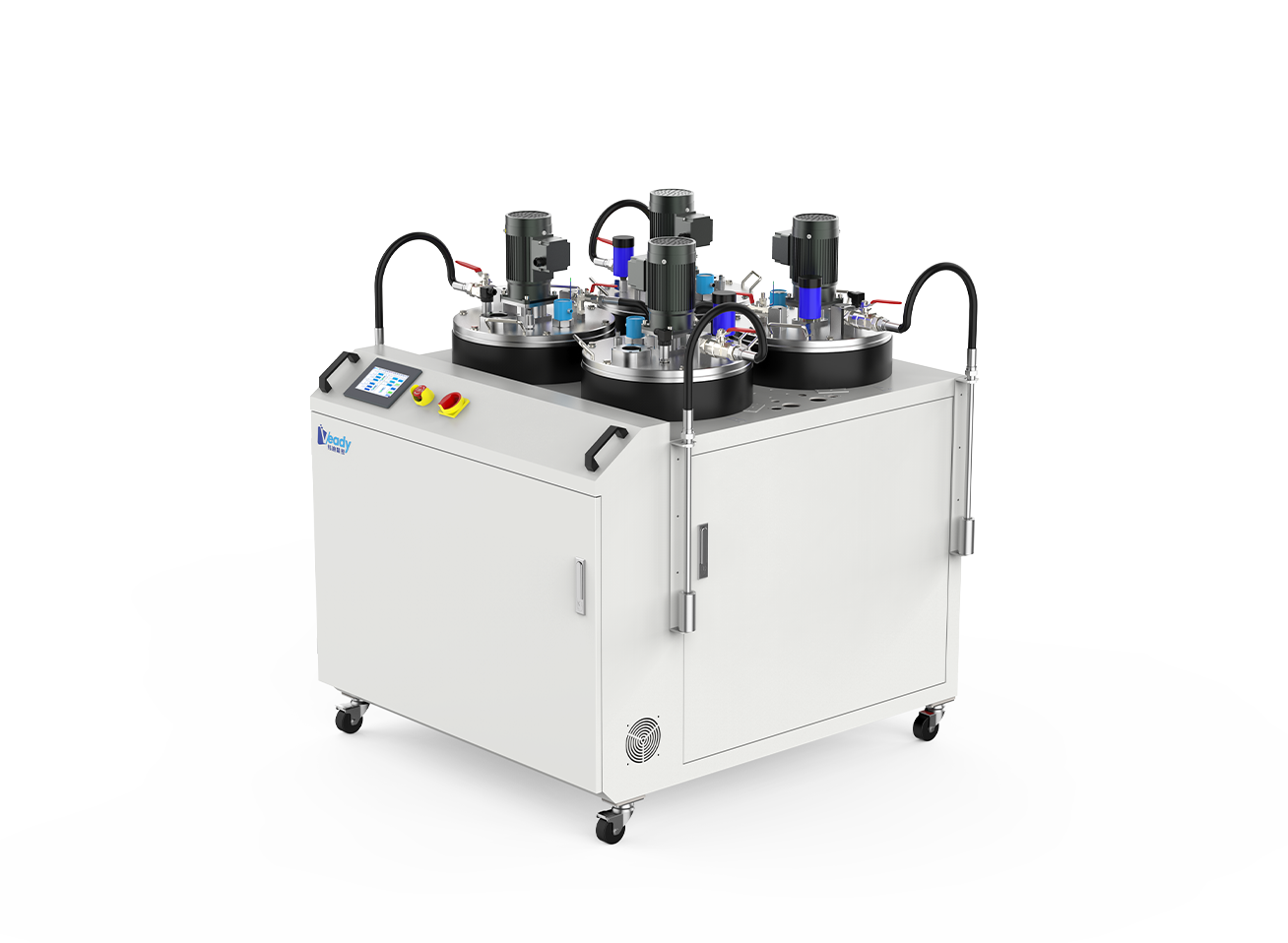

1. Adopt PLC+HMI human-machine interface Control System.

2. Double barrel design, A glue and B glue are stored separately, sealed and stored, not easy to deteriorate.

3. Realize instant proportioning, instant mixing, and instant glue filling of two-component glue.

4. Configurable: dual-liquid screw valve, A/B switch valve, piston valve to achieve precise glue filling operations.

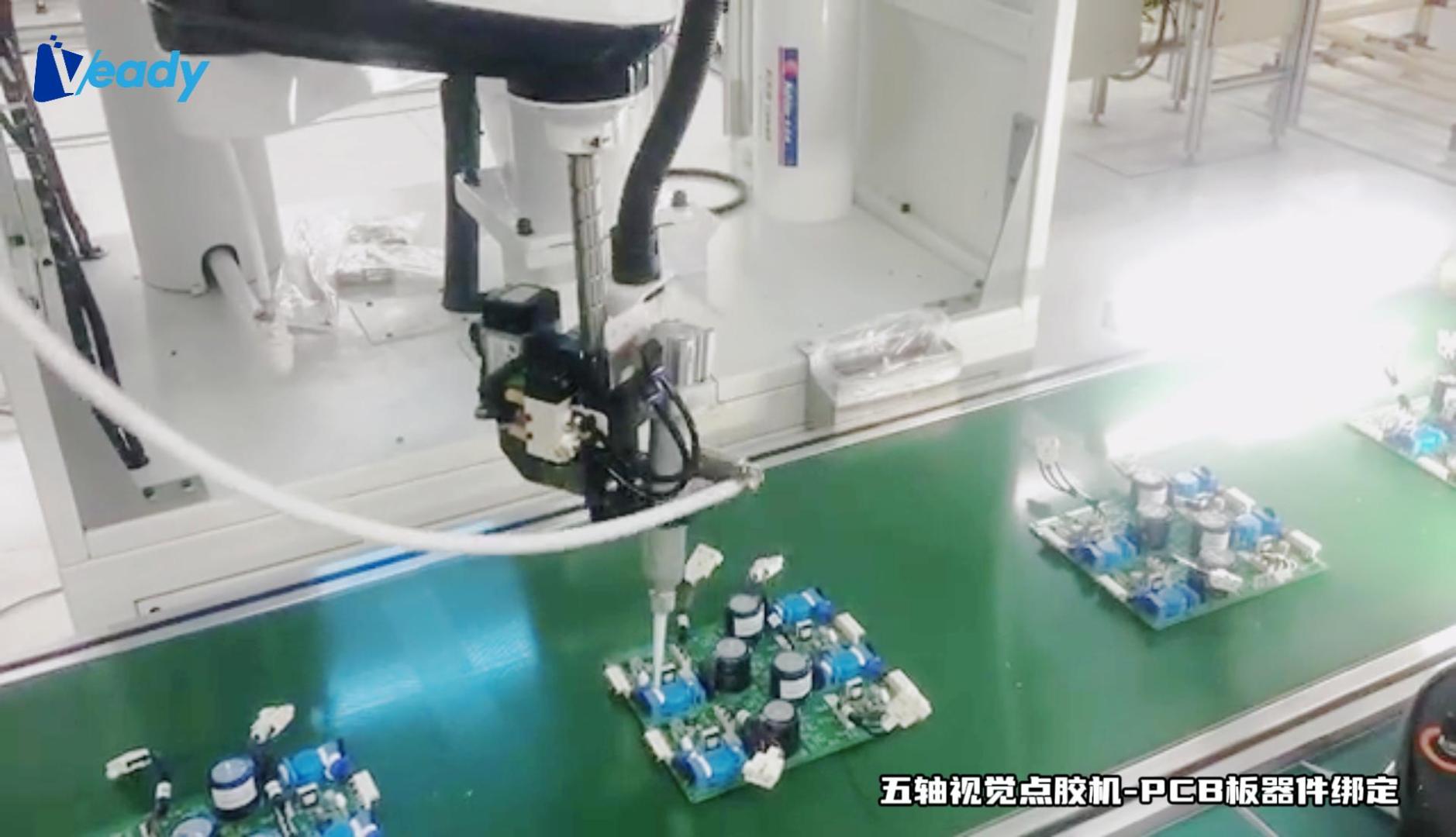

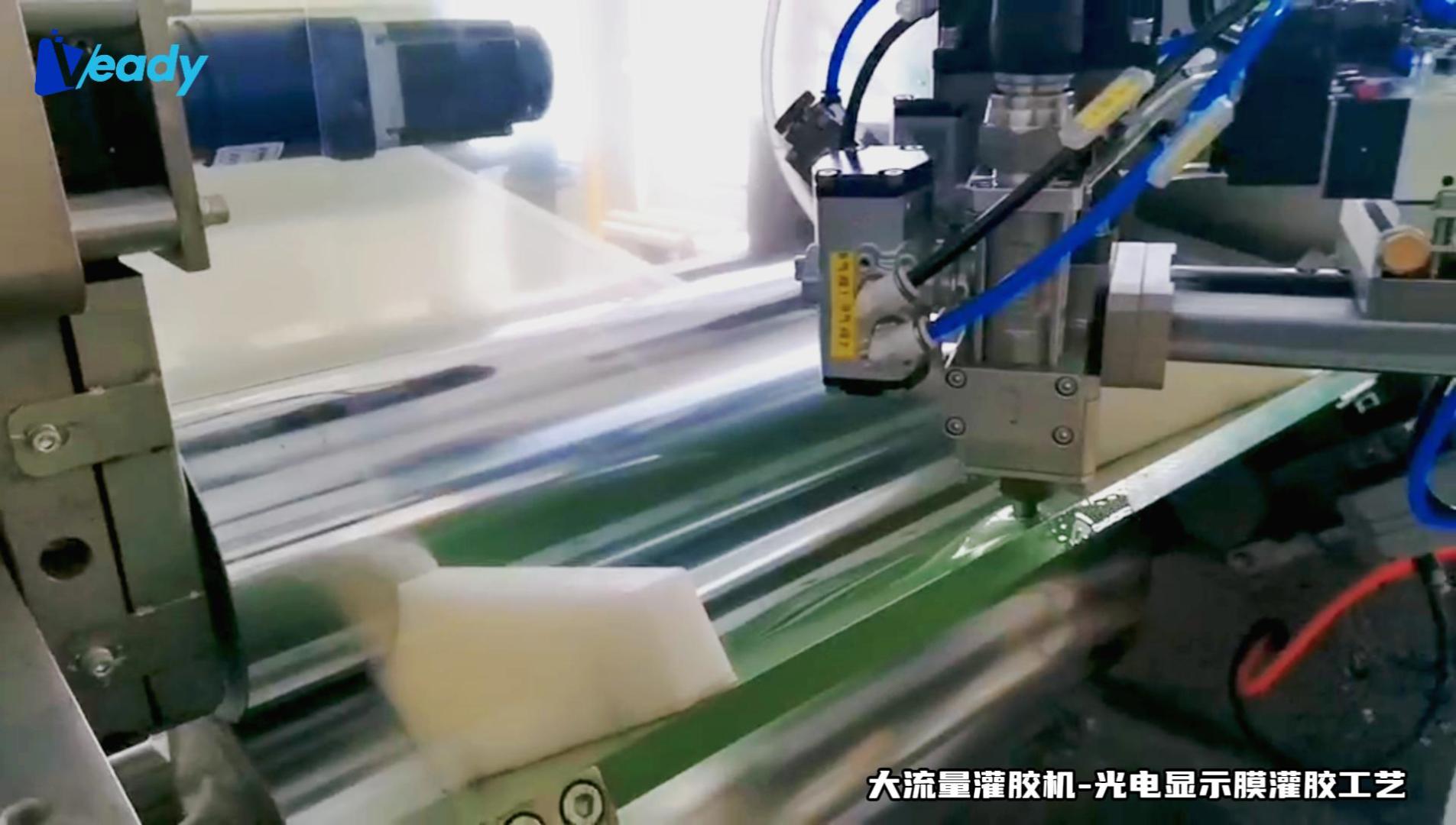

5. Compatible with automated equipment for dispensing, filling, and coating work stations.

Applicable glue: epoxy resin, polyurethane, organic silicone and other single/two-component glues.