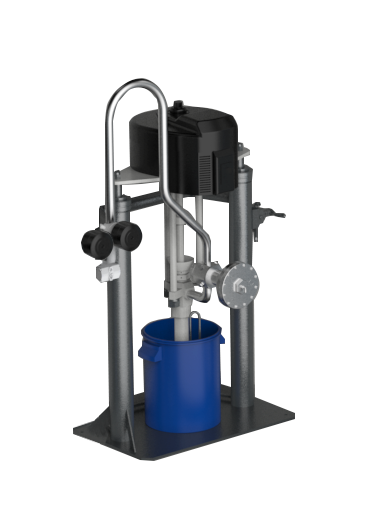

1. The two-component pressure plate feeding design allows for material change without stopping the machine.

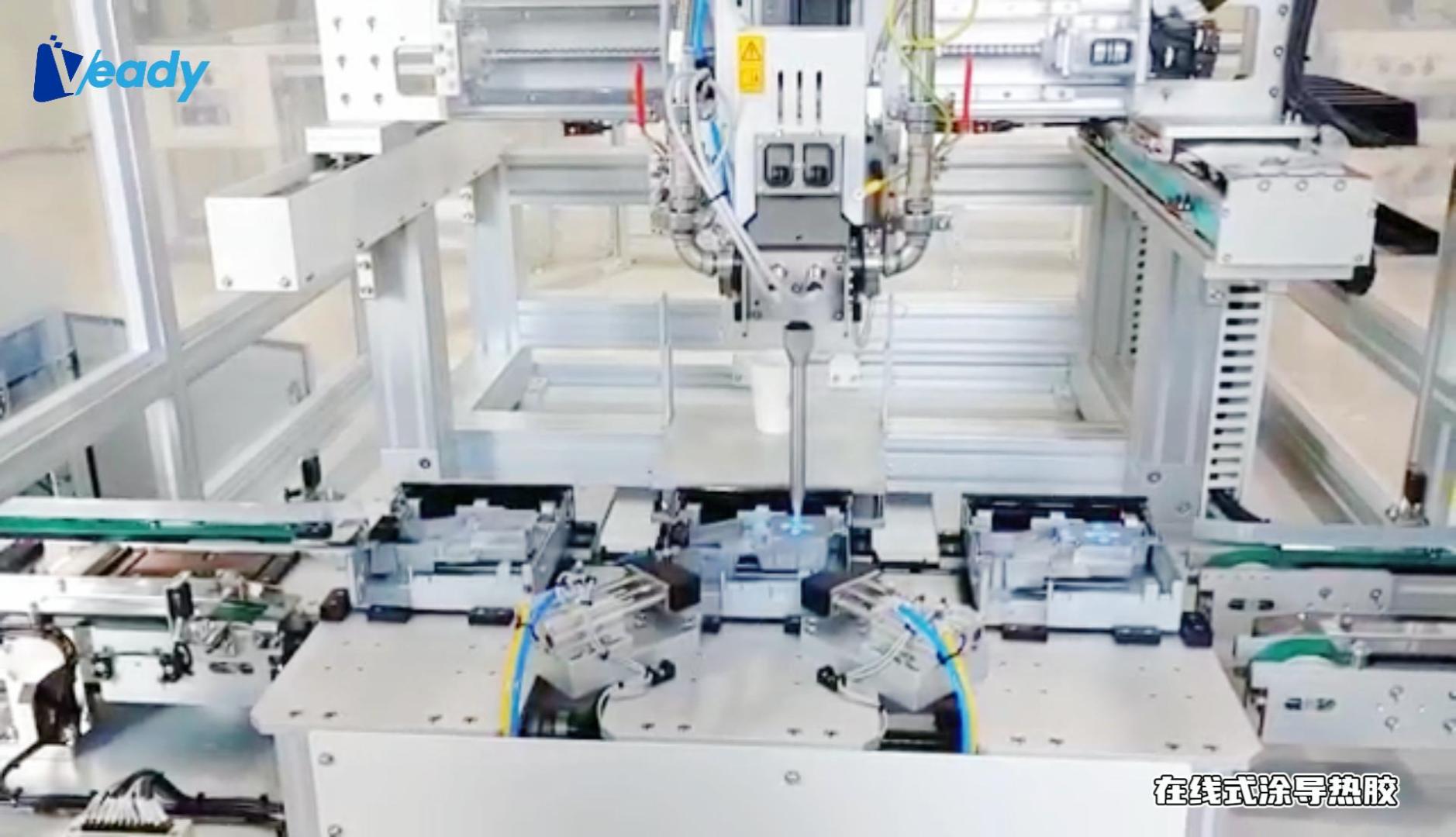

2. Equipped with liquid level detection and automatic switching of material supply, it can perform continuous gluing operations.

3. According to the characteristics of the glue, the glue supply pump body, pressure plate, and pipeline heating functions can be selected.

4. Suitable for feeding and conveying high-viscosity two-component glue.

5. The modular design of the equipment facilitates daily maintenance by customers.

6. The equipment process parameters are uploaded to the bus through Ethernet to ensure the traceability of the product's production process.

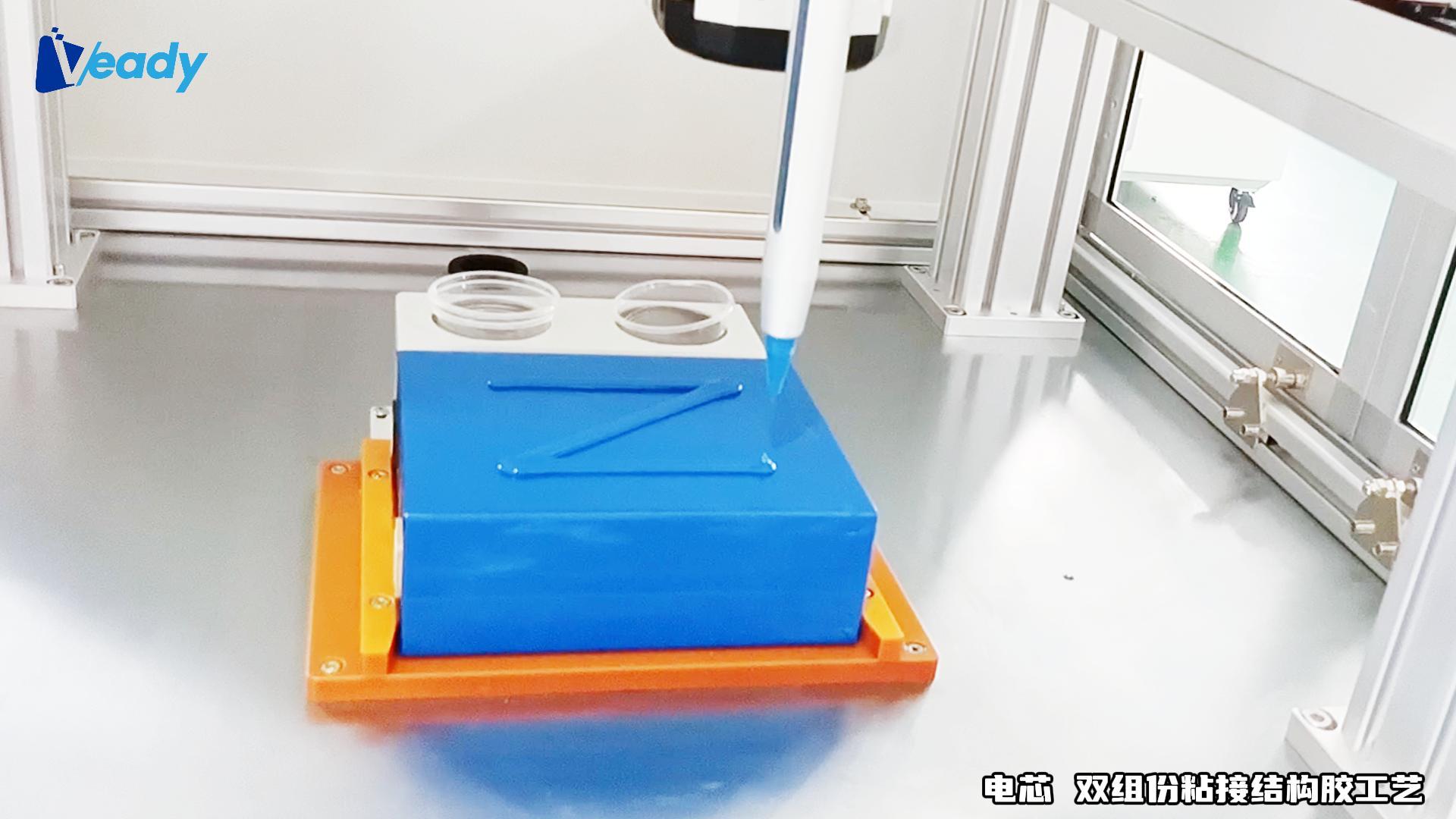

Applicable glue: two-component thermally conductive glue, sealant, structural glue and other two-liquid materials.

Application fields: Gluing of power batteries, energy storage batteries, PACK boxes, battery modules, solar photovoltaics, automobile parts, etc.