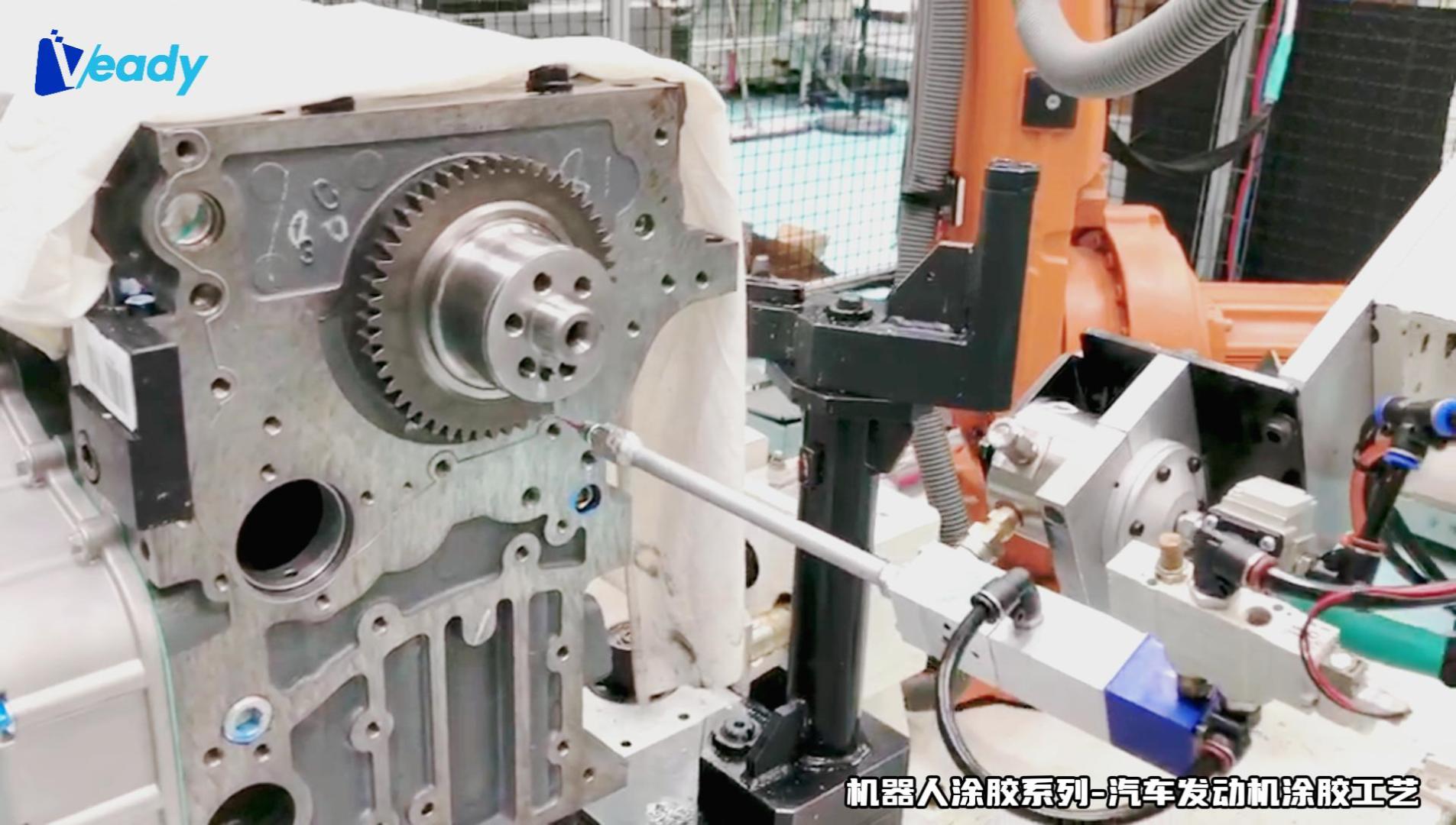

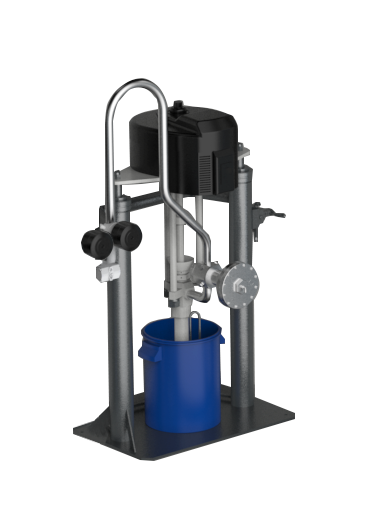

1. It is Composed of a 55 gallon pressure plate for glue supply, a NEV4545 transfer system, a variable ratio quantitative machine, a six axis robot, and a 3D glue path detection module

2. Optional: functional modules such as flow meter, automatic needle alignment, visual positioning, nozzle cleaning, and adhesive path detection

3. Configuration: high-flow dual-servo quantitative machine, static Hybrid Approach glue dispensing.

Applicable glue: two-component thermally conductive glue, sealant, structural glue and other two-liquid materials.

Application fields: Gluing of power batteries, energy storage batteries, PACK boxes, battery modules, solar photovoltaics, automobile parts, etc.