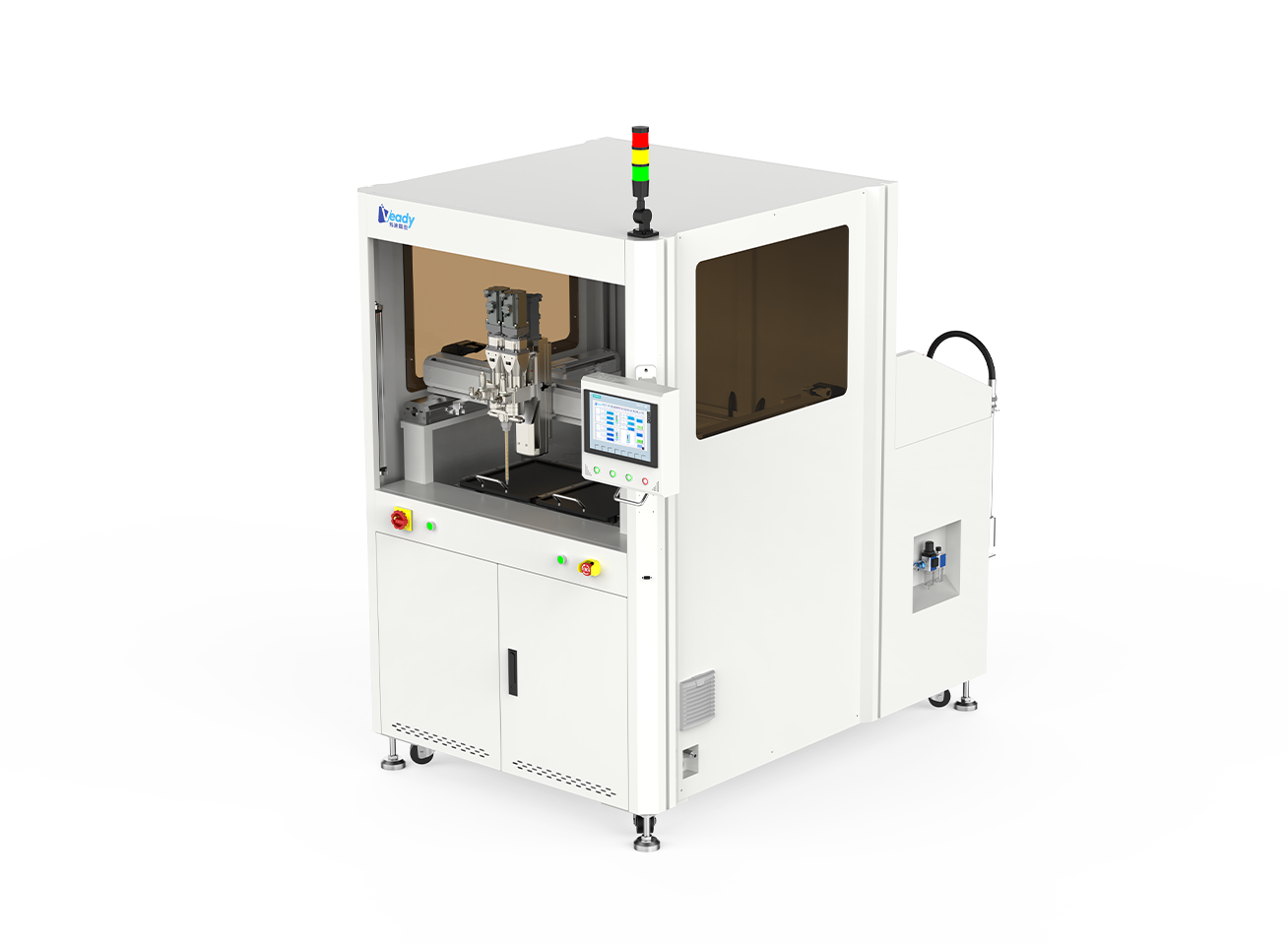

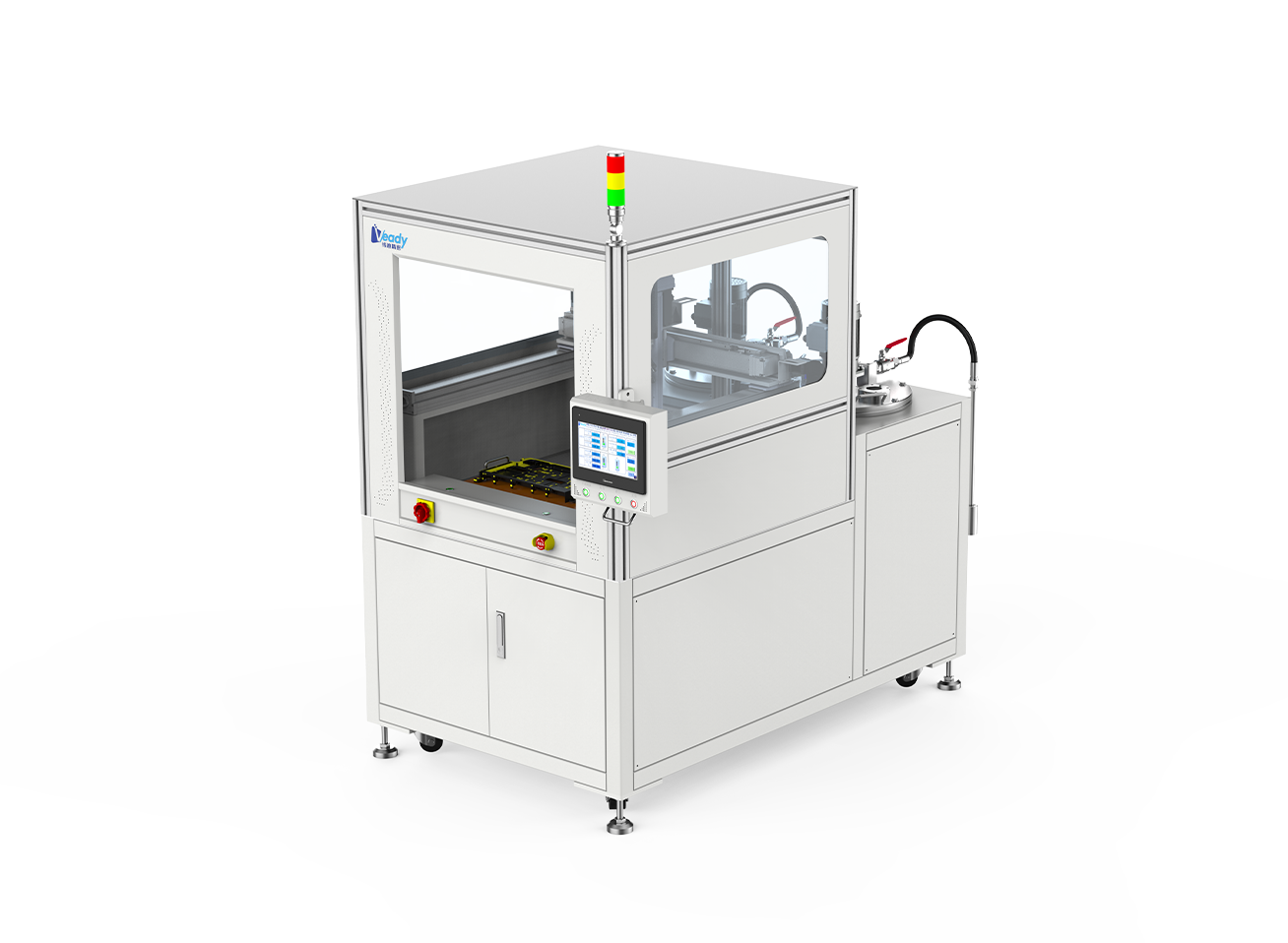

1. Gantry-type three-axis operation module, realizing point-to-point, straight line, shaped, circular arc interpolation and other graphic trajectory filling.

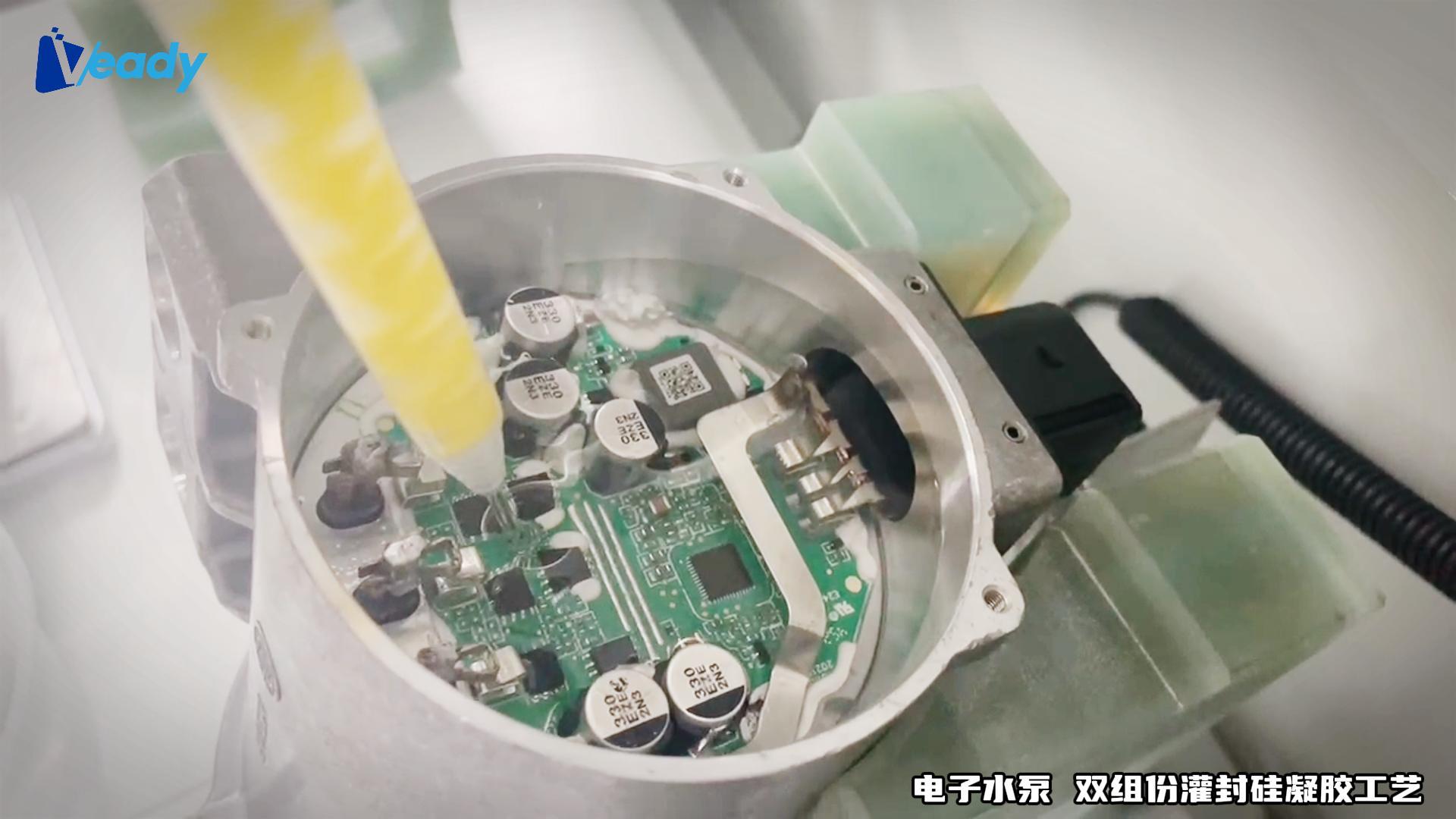

2. Independent research and development software system, realize two-component glue instant proportioning, instant mixing, instant filling operation.

3. Material Preparation Systems can be equipped with gear pumps, screw pumps, piston pumps, diaphragm pumps Feeding Method according to the characteristics of the glue.

4. The barrel is made of SUS304 stainless steel, corrosion-resistant. Double material barrel design, sealed storage, not easy to deteriorate, capacity 10L, 20L, 45L, 60L optional.

5. Glue barrel is equipped with constant temperature heating, motor stirring, vacuum defoaming, liquid level sensor, pipeline pressure monitoring and other functions, with abnormal alarms and interface prompts.

Applicable glue: epoxy resin, polyurethane, organic silicone and other two-component glue

Application areas: motors/motors, hall coils, microswitches, automotive electronics, precision sensors, ignition coils, lithium power, energy storage batteries, solar photovoltaic and other industries.